Welcome to Pavasaurus! Our jargon-busting glossary to help explain the terminology and phrases used within the paving and landscaping world. This landscaping lexicon is illustrated as much as possible, as a picture is worth a thousand words.

If you run across anything that needs explaining or need any help and advice about your patio or driveway paving project, don’t hesitate to contact us.

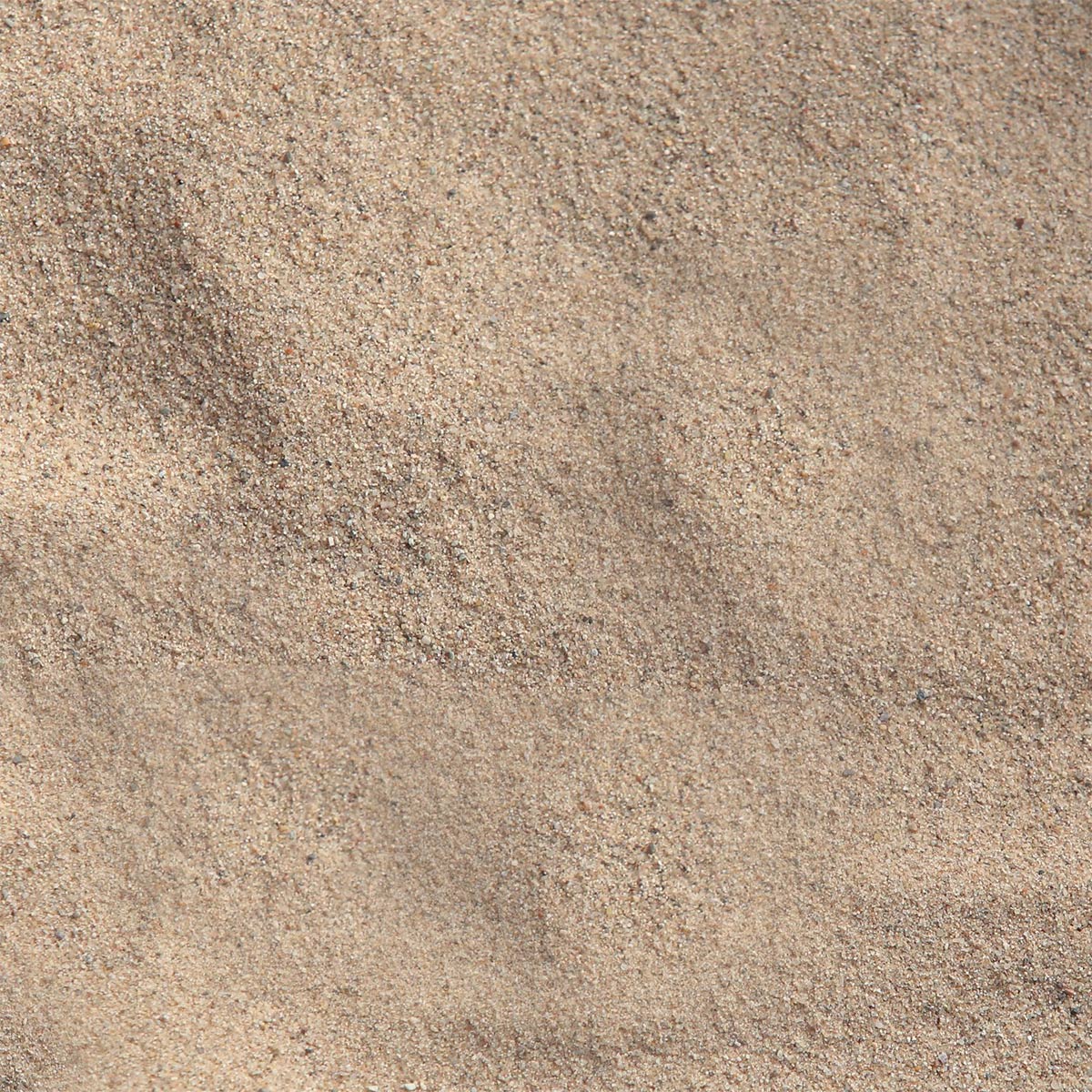

- Aggregate

- Crushed and particulate rock and stone materials such as sand, gravel and hardcore that are used in construction and paving for a variety of purposes. They are sold based on particulate sizes and grade/quality. Common aggregates used in paving and patio installations include sharp sand and MOT Type 1 (Type 1 SHW clause 803).

- Air Voids

-

In the context of paving, there are two types of air void.

- Sub-base – where the aggregate, MOT Type 1 (Type 1 SHW clause 803) has not been properly compacted, leaving air voids in the sub-base. These generally occur when an installer tries to compact too greater depth of hardcore in one go. Rather than trying to compact 150mm of MOT Type-1 at once, three consecutive 50mm layers can be compacted, to ensure each layer is fully compacted. This approach will mean there is less chance of any air voids being formed.

- Laying course – where the installer has used either dot-and-dab or framing of the bedding mortar rather than a full bed of mortar to lay the slabs. Both dot-and-dab and framing should be avoided as the air voids create a range of potential issues (including weaker bonds, more chance of slabs coming loose, damp and water filling the voids creating staining, efflorescence, chemical and physical erosion and also differential weathering for concrete slabs that cure unevenly due to damp and water pooling in the voids).

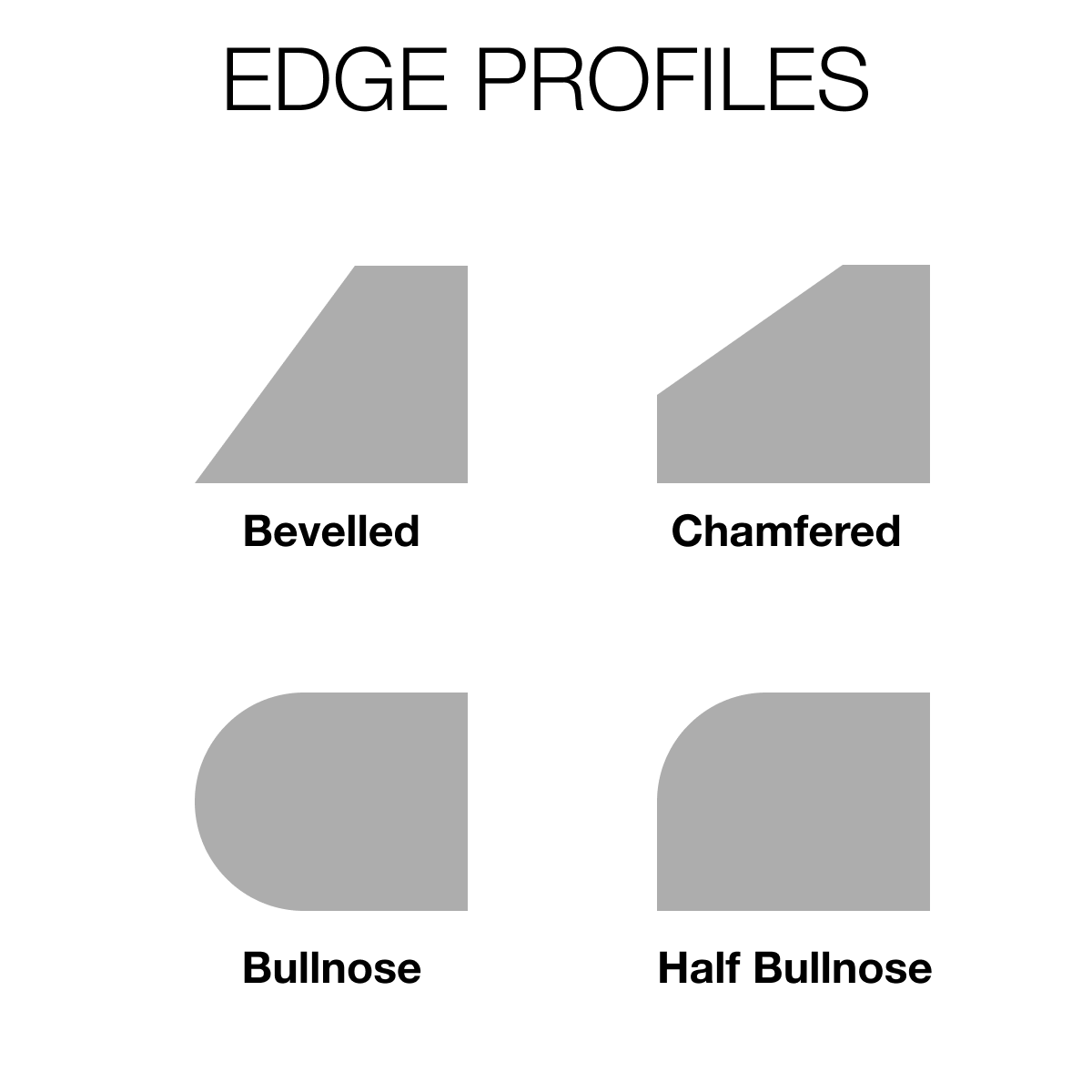

- Arris

- The edge where two paving slabs or blocks meet. There are a variety of profiles which include bull-nosed, half-bull-nosed, chamfered, bevelled (see below).

- Asphalt

- The bitumen and aggregate mix used for constructing metalled-road surfaces. Asphalt is weatherproof, durable and provides excellent traction and grip, which is why it is used on most public roads. It is often referred to as tarmac, a shortening of Tar MacAdam, a name for the process invented by Welsh engineer Edgar Purnell Hooley in 1902. Hooley took the MacAdam cambered road structure and added tar as a bonding and weatherproofing agent to provide Tarmac roads the cohesion, durability and grip we now take for granted. Asphalt is the updated version of this process, that replaces tar with bitumen.

- Asphalt Chip

- The process of adding fine aggregate chips to the surface of an asphalt road using an emulsion binder to provide enhanced grip for vehicles and reduce road wear. Using light-coloured aggregates can also help reduce road heating, with the surface providing higher degrees of reflectivity. Locally sourced aggregates are also often used as asphalt chips to help the road blend in with the surrounding countryside.

- Ballast (Washed)

-

Ballast is an aggregate that is often used in building and landscaping to make concrete. It usually incorporates a range of particulate sizes from sharp sand up to 20 mm. It is typically washed, so has lower fines and no clays or dust.

Its main use is as the aggregate in concrete, where its larger particulate sizes means it creates a stronger, more durable structure good for footings, foundations and base slabs.

- Bed / Bedding

-

The colloquial name for the Laying Course, the bedding layer is the material upon which the paving is directly laid. The bedding layer sits directly underneath the paved surface or binder course, and on top of the sub-base.

The functions of the bedding layer are:

- To allow paving units to be adjusted to level

- To be shaped so paving units can be manipulated and laid in desired locations

- To support the paving units

- To provide a cushion between the paving and the sub-base

For patios slabs, a full bed of paving mortar (5:1 ratio cement mix) is used as the laying course.

For driveway block paving, a bed of screen sharp sand is used as the laying course.

- Bedding Mortar (hydraulically bound laying course)

-

This is a cement mortar using Ordinary Portland Cement (OPC) with a coarser sand aggregate (usually sharp sand 0.63–2.0mm particulates). You want a drier mix, so use just enough water to make the mortar malleable. Bedding mortar should use a 5:1 ratio of sharp sand (aka grit sand) to general purpose cement to ensure it is strong and has good bonding properties.

- 5 parts sharp sand

- 1 part general purpose cement

- water (just enough to mix the mortar, e.g. it should be a relatively dry cement mix)

Bedding mortar should be used in conjunction with priming slurry to ensure that there is a very strong bond that will prevent your paving coming loose.

- Belgium Block / Pavé

- A synonym for a sett (a rectangular dressed quarried stone paving block) that is generally rectangular. Belgium block is a traditional square-cut natural stone used for paving road surfaces and driveways. The most common types used in the UK are sandstone setts and granite setts.

- Bevel / Bevelled Edge

- Similar to chamfer, a bevel is an edge profile where the original perpendicular faces are bisected by an angle. However, unlike a chamfer (which has three faces) a bevel only needs to have two faces visible.

- Bitmac

- A compound of the words Bitumen and MacAdam and alternate name for tarmac/asphalt.

- Block Paving (Paving Blocks)

-

Smaller format pavers that are thicker (30-80mm) than patio paving and suited to higher compression and loads. This makes them ideal for driveways and parking areas. These encompass concrete block paving (BS EN 1338) and natural stone blocks and setts (BS EN 1342).

As well as being used for driveway paving, block paving is also commonly used in landscaping for garden pathways, borders and edging, often being used decoratively for paving features, patterns and motifs.

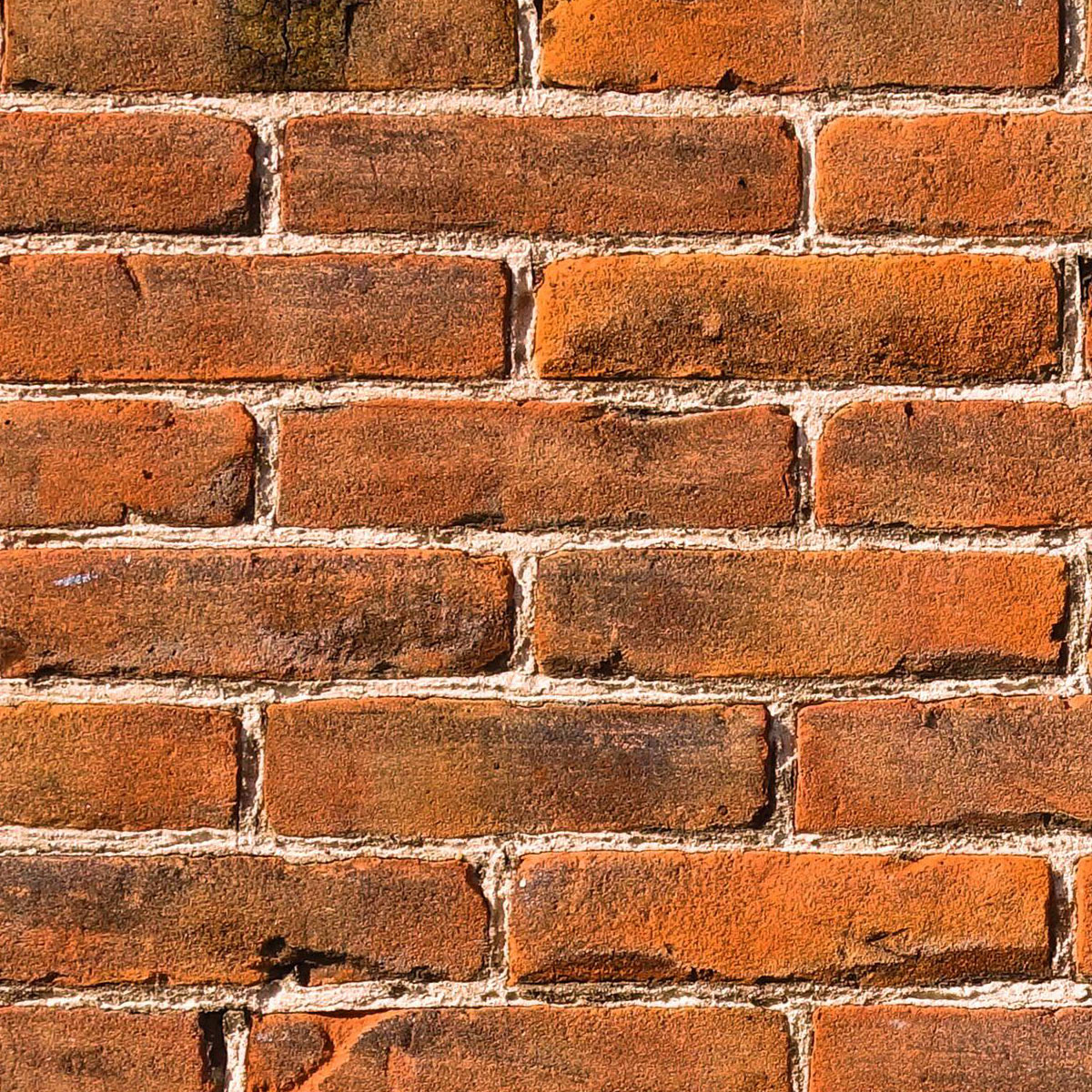

- Bricklayers Sand

- See Building Sand

- Bricklaying Mortar / Masonry Mortar

-

Bricklaying mortar in the UK is usually made with a 4:1 ratio of building sand to Ordinary Portland Cement. Water is added, so there is just enough to create a workable and creamy texture. The higher cement ratio in 4:1 bricklaying mortar improves the bond strength needed in structural walling and masonry construction.

Most bricklayers nowadays will also use a mortar plasticiser additive to the cement mix that will make the mortar much more workable (more cohesive and elastic).

- Building Sand / Builders Sand / Bricklayers Sand / Masonry Sand / River Sand / Plastering Sand / Soft Sand

-

Building sand is a medium sand (ISO 14688-1:2002) and falls in the grade of 0.2–0.63mm in particulate / grain size. As its synonyms suggest, building sand is used in bricklaying and masonry mortar, render and plaster.

- Brick & block laying mortar

- Masonry mortar

- Render

- Plaster

- Builders Sand

- See Building Sand

- Bullnose / Bullnosed

- Bullnose is a term used in the landscaping and building industries to describe convex profiles (i.e. a rounded trim) of construction materials, and it is especially used with regard to masonry and bricks.

- Cassie

- Scottish colloquial name for a sett/cobble or cobbled/setted street – derived from causeway.

- Causey

- A colloquial Scottish and north of England term for a cobbled or setted street (as opposed to flagstones) – derived from causeway.

- Causey Edge

- Yorkshire/Northumberland colloquial term for the kerb.

- Cement (CEM I, CEM II, CEM III, CEM IV, CEM V)

-

Cement is a binding substance used in construction and landscaping that sets, hardens and adheres with materials such as sands and aggregates when it is mixed with them to create concrete, mortar or render.

In landscaping when we refer to cement, we generally mean Portland cement, a fine grey powder manufactured from common minerals (Limestone – CaCO3, Alumina source – Al2O3 Iron ore – Fe2O3 and Silica source – SiO2) which are mixed together and fired in a kiln to ± 1450°C to create a binder with hydraulic properties called clinker or k. Clinker is an intermediate product of small lumps or nodules of heat fused material. This clinker is crushed and ground into a fine powder (usually with 5% gypsum added to prevent flash setting) to create Portland cement.

There are five types of cement used in the UK under the B.S. EN 197-1 standard:

- CEM I – “Pure” Portland clinker: with a maximum of 5% minor additional constituents (Ordinary Portland Cement / OPC).

- CEM II – Composite cement: Portland clinker + upto 35% additives (e.g. fly ash, slag or limestone).

- CEM III – BFS-OPC: blast furnace slag cements (type A 35-64% clinker, type B 20-34% clinker, type C 5-19% clinker).

- CEM IV – Pozzolanic cement – pumice or volcanic ash (type A 65-89% clinker, type B 45-64% clinker) – see Roman concrete

- CEM V – Composite cement

- Cementitious

- Having properties like cement (e.g. it will set and harden when water is added).

- Cement Mix

- General term for a mortar mix using Ordinary Portland Cement (aka General Purpose Cement) such as 4:1 bricklaying mortar or 5:1 paving bedding mortar.

- Cement Type Nomenclature

-

In addition to the five main cement classifications (CEM I-V), there are also additional designations that indicate performance and constituents.

- 28-Day Strength – grades are 32.5, 42.5 and 52.5 (often listed 33, 43, 53).

- Strength Gain Speed – the ratings are R (early strength gain), N (normal strength gain) and L/S (low or slow strength gain).

- Additive Code – V (fly ash), S (slag) and L (limestone)

- Chamfer / Chamfered

- Chamfer is a term used in the landscaping and building industries to describe a transitional angled-edge between two perpendicular faces (e.g. a three-faced profile). A chamfer profile has the “point” of the corner between the two faces removed, with a shallower angle. Chamfers most commonly are set at a 45° angle, as this evenly bisects both faces of a 90° object. A chamfer will always have 3 parts to its profile visible – the original perpendicular faces and the angle (e.g. 0°top, 45° angle, 90° side). This differs to a bevel, which can be a two-faced profile.

- Cobble / Cobblestone

- Technically a cobble is a rounded stone clast (river stone) with dimensions between 64-256 mm (larger than a pebble, and smaller than a bolder). Traditionally, these rounded river stones were used to pave roads and carriageways. They were laid on their side, set deep into the mortar, with the edge facing up. This arrangement gave cobble paving great strength and durability. Because, cobbles/cobblestone were used so ubiquitously for paving roads, the word is now used synonymously for any traditional looking stone block paving or sett.

- Cobbled

- Paved with cobbles/cobblestones (setts).

- Compaction

- The process in which aggregates such as hardcore (MOT Type-1) or sharp sand are compressed to stabilise, strengthen and remove voids from within the material to provide a stable compacted base on which other materials can be laid. When laying a patio or driveway, compacting will usually be done using a wacker-plate. This is a vibrating mechanical device that looks similar to a lawn mower – it uses a flat plate on the underside to compress/compact the ground, driven by a mechanical ram that also vibrates.

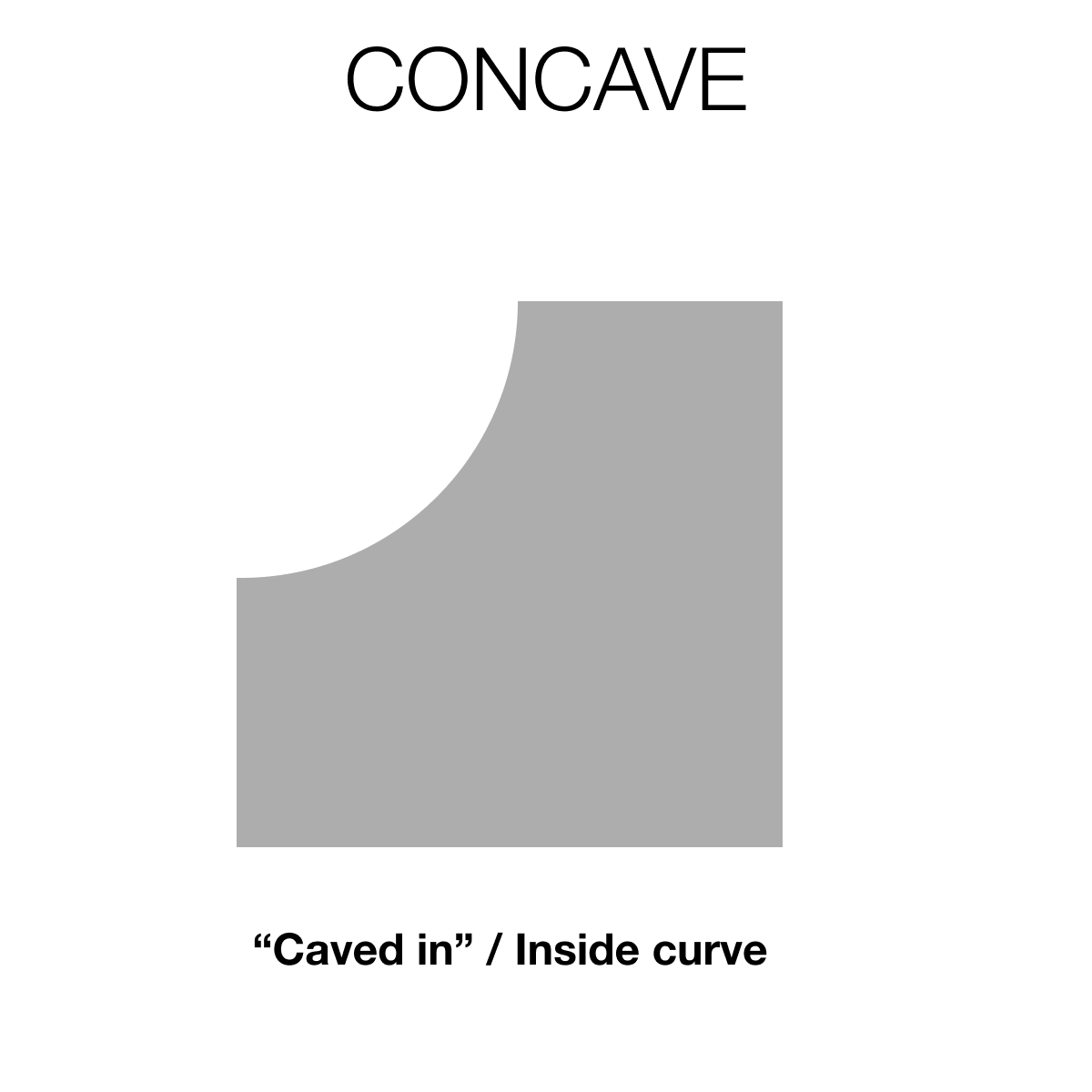

- Concave

- A rounded or curved profile of a shape where the rounded bit pushes in (e.g. the inside of a cereal bowl).

- Concrete Blocks / Breeze Blocks / Building Blocks / Cinder Blocks / Concrete Masonry Units (CMU)

-

Their formal name is Concrete Masonry Units (CMU), but most builders and landscapers refer to them as concrete blocks or breeze blocks. They are the structural construction blocks used in housebuilding and landscaping, manufactured to comply with BS EN 771-3.

Breeze is an older name for ash/cinder, which is often a constituent material in their manufacture. This, is the origin of their common name, breeze blocks (and hence why the common American name for them is “cinder blocks”).

They are generally sold as either low density, medium density or dense and common strength ratings are 3.6N, 7.3N and 10.4N. The common size formats are:

- 440 x 215 x 100 mm

- 440 x 215 x 140 mm

- 440 x 215 x 215 mm Hollow

- 215 x 215 x 100 mm Course Adjusting Brick

- 350 x 300 x 100 mm Foundation Block

Their function is structural. For double-skin walls, they will generally have an either exterior skin of facing bricks, or be directly rendered or clad to provide an appropriate aesthetic. For interior walls, stud work & plaster board or plaster are used to provide an appropriate finish.

- Contractor Pack

- A paving industry term to describe a mixed-size pack or crate of paving slabs or blocks.

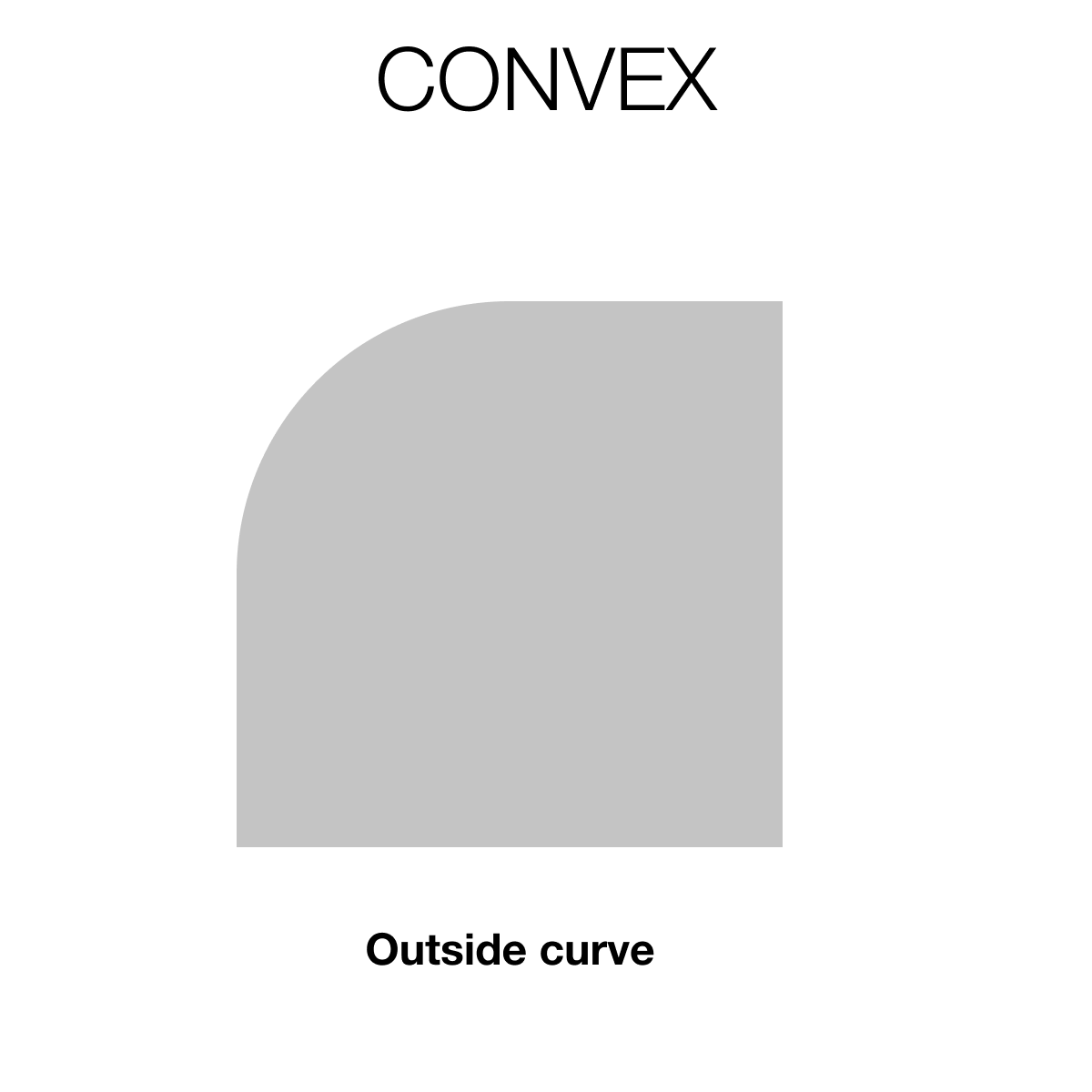

- Convex

- A rounded or curved profile of a shape where the rounded bit pushes out (e.g. the outside of a football).

- Coping / Coping Stones

- Masonry units, usually of stone, concrete or bricks that usually forms the top of exterior walls. Coping is designed to protect the wall from rain and other weather entering the top of the wall. If left unprotected, the wall could be damaged by water/damp, weakening its structural integrity and shortening its life.

- Cube / Cubed

- Volumetric measure based on length-height-width expressed as metres-cubed (m³). An object that is 1m-long by 1m-high that has a 1m-width/depth will be 1 cubic metre (1m³) in volume.

- Coarse Graded Aggregate

- This is an aggregate with reduced or no fines (small particles/dust). MOT Type 3 SHW Clause 805 which is used for the sub-base in permeable paving installations is the most common Coarse Grade Aggregate.

- Delamination

-

The process by which layers of stone become loose and come away from paving slabs. This really only occurs with limestone, sandstone and slate, which are sedimentary rock where they have a riven surface.

Generally, delamination is a minor issue, and the underlying paving slab is left unaffected and sound.

Sedimentary rock is layered over time in sheets of sediment which fuse together under gravity, pressure and chemical bonding to become laminated (layered together).

When chemical erosion (e.g. acid rain) or physical erosion (e.g. freeze-thaw) of paving stones occur, the outer layers of the laminated rock structure are weakened and flakes of rock will become loose and detach from the slab (delamination).

Don’t worry too much about delamination – it is a natural process, and the slab is usually unaffected when smaller flakes come away.

Do be carefully with high-pressure washers, as these can get between layers of rock on a riven surface, and weaken the stone, and cause delamination.

- Differential Weathering / Curing

-

This is caused by different levels of moisture being present in the concrete (especially the surface) in the early stages of the concrete’s life (first 4-12 weeks). When concrete cures at different rates, its chemical composition and hue can alter, and these differences in moisture levels appear as differential curing / weathering.

What causes these differences in concrete moisture that trigger differential curing?

- Water pooling and damp from voids in the bedding layer (dot & dab / framing)

- Surface water pooling & poor drainage (improper fall/gradient and dips in the patio level)

- Bedding mortar moisture transfer when the mix is too wet

- Subsurface moisture uplift/osmosis where a priming slurry or SBR bond has not been used during installation

- Items left on the concrete patio when it is first laid (timber, plastic, pallets & packs of building materials)

- Splash zones from blocked/obstructed down-pipes and guttering

- Double Stretcher (Edge Course)

- It is common practice to use an edge course with block paving. A stretcher bond laying pattern see the blocks laid end-to-end with alternate rows being staggered, so one row’s joints are aligned with the centre of the other rows block. A double stretcher simply means where two rows are used in the edge course, and they are laid using a stretcher bond pattern.

- Dot & Dab

-

A colloquial name for the practice of applying minimal mortar (dabs) in each corner (sometimes with a central dot) when laying paving slabs. It was originally conceived as a cost saving. However, dot and dab creates many potential issues for your patio from the voids that are created and weak bonding. This technique should NEVER BE USED. Always install paving slabs on a full mortar bed.

- Issues #1 – voids under the slabs: moisture can pool, creating damp patches & discolouration

- Issues #2 – voids under the slabs: moisture/damp can erode and weaken the slab (chemical and frost-action erosion)

- Issue #3 – voids under the slabs encourage burrowing animals and weed growth

- Issue #4 – weak bonding with the slabs – loose slabs, rocking slabs and trip hazards

- Issue #5 – unsupported slabs – larger spaces / voids between the supporting bedding mortar dots increase the chance of slabs cracking under load (e.g. traversing with a heavy wheelbarrow or similar load).

- Drainage

-

For domestic driveways in the United Kingdom, surface water capture within the boundary of the property is recommended (unless you wish to apply for planning permission). This can be done by using underground drainage and soak-away crates or by using permeable paving blocks.

For commercial paving projects and housing development, your planning application will need to address surface water management and drainage as part of your SuDS planning.

Most domestic underground drainage will be gauged at 110 mm (although 160 mm and 200 mm are also used), with complementary drainage channels, hoppers, inspection chambers and couplings to allow you to configure the drainage layout to your specific needs.

- Driveway Paver / Driveway Paving

-

These refer to either of the two types of paving unit commonly used for driveway. These are concrete paving blocks (manufactured in accordance with BS EN 1338) or natural stone setts (manufactured in accordance with BS EN 1342).

The format of driveway paving blocks is smaller and thicker than a patio slab. The smaller surface-area and added depth of driveway pavers means they are able to handle higher loads and greater compression. This prevents them from shearing or cracking under the weight and movement of vehicles.

- Dropped Kerb

- Dropped kerbs allow for vehicles to cross the public pavement to get to a private driveway. If you are creating a driveway at home and no dropped kerb exists, you will need to apply to your local authority and pay a fee for them to convert the kerb outside your home to a dropped kerb.

- Edging

-

Edging and edging stones are masonry units used to create physical transition or borders for paving areas and gardens beds or lawns. There are three main types of edging:

- Garden edging – linear units pieces stone, concrete for ceramic/fired-clay used to define the edges of flower beds, borders and lawns.

- Paving edging – smaller pavers (usually setts of paving blocks) used to picture-frame or border the paving area as a decorative motif.

- Edge restraints – concreted and haunched kerbstones or larger blocks use to create the perimeter of an area of block paving that holds the interior blocks in place.

- Edge Course

-

An edge course is the line of pavers (usually block paving or setts) that line the edge of a paved area. For block paving areas, the edge course will include edge restraints (often kerbstones) which are haunched with concrete to hold the interior blocks in place. More often than not, the edge course will use a contrast colour to the rest of the paved area to provide visual differentiation.

An edge course fulfils multiple functions:

- Structural – used as edge restraints, the haunched course holds block paving in place

- Practical – edge of a pavement is laid intact, creating a neat, orderly edge (e.g. no cutting or irregular sizes)

- Practical – they make cutting in the pavers easier (giving you a profile/guide against which to mark & cut)

- Practical – the edge restraints are laid and haunched before installing block paving, so they can be used as level guides when screeding the sharp sand bedding layer.

- Aesthetics – they provide a visual border or picture frame to the paved area, better defining the space.

- Edge Profile: Hand-Cut Paving

-

Hand-cut paving has been cut to size and edged using a masonry chisel. The profile of the slab will typically have an inverted bevel appearance where the mason has cut the stone to a specific dimension.

The edge will be slightly sharper and more angled than a tumbled edge, and the profile line along the edge of the paver will be truer/straighter than a tumbled paver.

Hand-cut paving will tend to be laid with medium width joints (standard jointing).

- Edge Profile: Straight Sawn Paving

-

Straight sawn edge paving is where the paver has been cut with a mechanical saw or water jet cutter to create a straight edge.

Because both mechanical saws and water jet cutters came into being during industrial mass production and industrial digitisation respectively. Consequently, straight sawn edges are associated with modernity and contemporary aesthetics, as this is when they came into consciousness in architectural and hard landscaping.

Straight sawn edged pavers can be narrow jointed as their edges offer more precise laying options, although butt-jointing (where paver touch each other) should always be avoided.

- Edge Profile: Tumbled Paving

-

Tumbled edge paving is designed to look older, more time-worn, and its purpose is to be used in more traditional settings with period homes and gardens where an antique or more rustic look and feel is required.

A tumbled paving slab has a softer, more rounded profile where the sharper edges have been smoothed and worn off during the tumbling process.

Tumbled edge slabs and blocks will tend to have wider joints when laid, as edge profiles and less true and more irregular.

- Edge Restraints

-

As block paving is laid on screed sharp sand without the use of mortar, the matrix of blocks needs to be haunched on its perimeter with concrete to prevent them moving. This is the function of edge restraints – they create a fixed perimeter in which the block paving can be laid.

Kerbstones or larger blocks will be used as edge restraints and laid on mortar. Once properly positioned and levelled, the restraint blocks will be haunched with concrete.

The kerbstones/restraint blocks can be used as level guides when you come to screed the sharp sand for the laying course.

- Fall

-

A patio, driveway or other paving area needs to have a gradient to allow water to drain from the surface. That gradient is known as the fall.

For patios and driveways, a fall of at least 1:80 is needed, but if the surface of the pavers are rougher or quite riven, then a steeper fall of 1:60 is recommended.

- 1:80 fall = 12.5mm drop for every metre across

- 1:60 fall = 16.66mm drop for every metre across

Where possible, the fall should always drop away from the house. For driveways, this may not be possible if the public road is at a higher elevation than your property, so a drainage channel will need to be installed to capture surface water running down towards your home off the driveway.

- Flag

- Technically a flag is the name for a larger concrete patio paver (concrete paving flags manufactured in accordance with BS EN 1339). However, because concrete paving is often used to create a low-cost alternate to time-worn antique flagstones, the word is more closely associated with the latter. Amongst landscapers in the north of the United Kingdom, flag is more commonly used as the generic name for a patio paver.

- Flagstones

- Sometimes used as a generic term for patio pavers (slabs/flags), flagstone is more commonly used as a way of describing traditional, period and historic slabs (or their reproductions). In other words antique paving or “ye olde” paving slabs.

- Freeze-Thaw Cycle Weathering (aka Frost weathering)

-

This is a type of physical erosion (that occurs with porous materials such as stone or concrete) when temperatures drop below zero (0 °C). Usually at night, as freezing conditions set in, moisture within the capillaries, micro-fissures and tiny cracks of stone or concrete forms as ice crystals. As ice is formed, it expands within the capillaries and fissures, forcing the stone or concrete apart, gradually weakening and damaging the paving or masonry.

During the warmer conditions of the day, melt-water then drains down further into the porous stone or concrete. That night, this water reforms as ice, which then expands within the capillaries, fissures and cracks, widening them, weakening the stone or concrete, and the freeze-thaw cycle of erosion continues.

In the United Kingdom, where average winter humidity is >85%, there is ample moisture and damp that will be present in the

capillaries, micro-fissures and cracks of stone or concrete if left unprotected. It is recommended to use an impregnating sealer on porous stone and concrete to help prevent water absorption, and consequently reduce the effects of freeze-thaw cycle erosion.

- French Drain

-

A perforated pipe buried in a gravel-filled trench that allows water that fills the trench to be collected and directed away. Named after Henry Flagg French who described them in Farm Drainage (1859). Typically, they are used to keep water away from building foundations, but in landscaping the are often also seen in the base of retaining walls to relieve groundwater pressure.

The gravel/aggregate should be coarse and washed (with fewer fines) to prevent the pipe perforations from becoming clogged. It is more common nowadays to see the pipe wrapped in geotextile permeable fabric to add improved protection to prevent clogging from fines.

- Frost Action / Frost Weathering

- A synonym for the Freeze-Thaw Cycle erosion.

- Full Bed of Mortar

-

This refers to using a complete covering of bedding mortar for your patio paving laying course. This phrase is used to differentiate and contrast from “dot & dab” and “framing” where only limited amounts of mortar are used to bed/bond the slabs. These methods leave voids under the surface of the slabs. With a full bed of mortar, there are no voids under the slabs and the slabs are fully bonded to the laying course.

You should always use a full bed of mortar to ensure the slab is fully bonded, stable and secure. A full bed of mortar has no voids, which can create a host of significant problems that will weaken and blemish the paving.

- Grade / Grading (Aggregates)

- The grade of an aggregate describes the distribution of particle sizes e.g. Type-1 is 40mm to dust.

- Gravel

-

Gravel is an aggregate of rock fragments with a particle size from 2 mm – 63 mm (ISO 14688-1:2002). There are three classification of gravel size:

- Fine gravel (2 – 6.3 mm)

- Medium gravel (6.3 – 20 mm)

- Coarse gravel (20 – 63 mm)

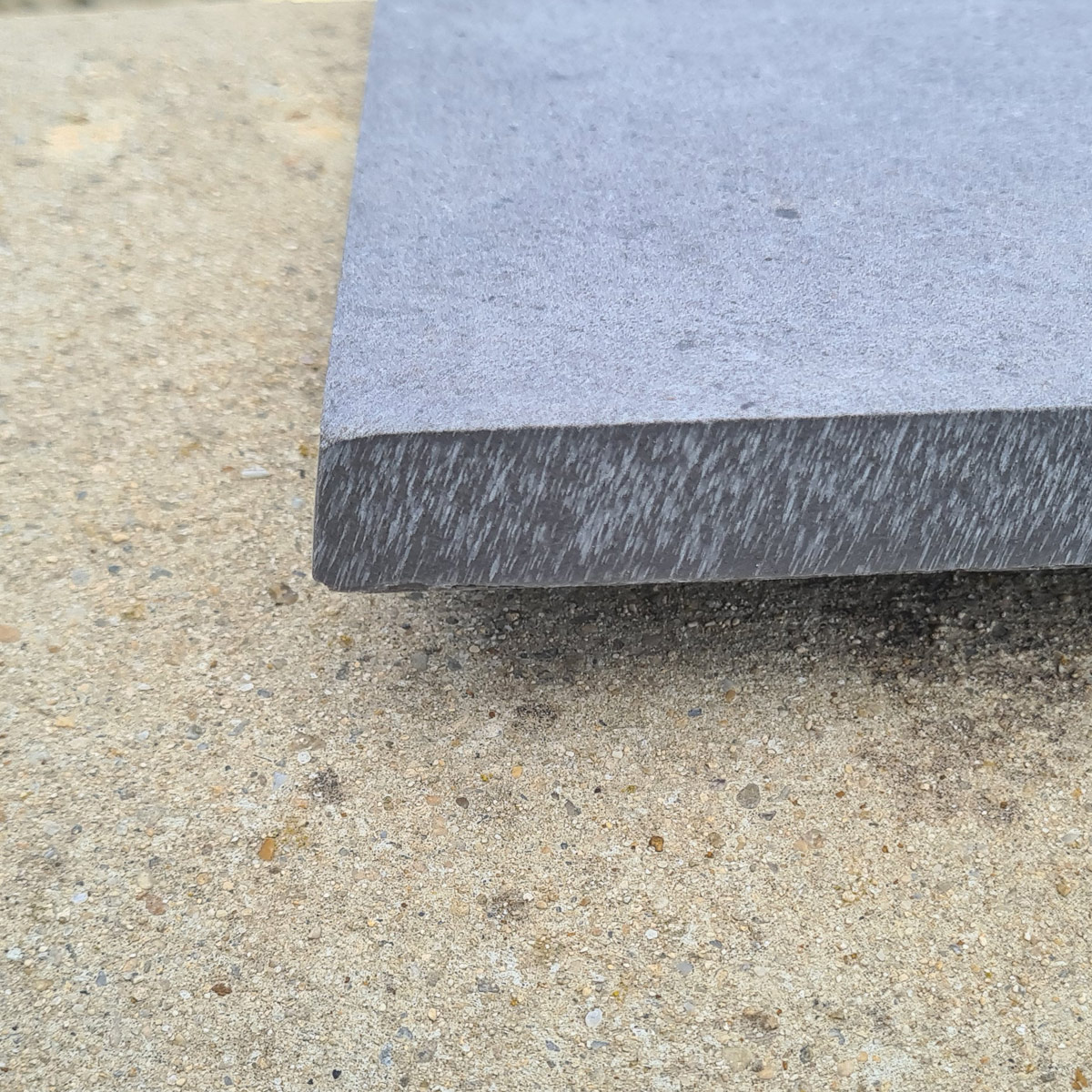

- Granite

-

Granite is an igneous rock composed mostly of quartz, alkali feldspar, and plagioclase. It is coarse-grained (phaneritic) so you can see the granules that were formed as the volcanic intrusion of magma slowly cooled as granite.

Granite is very hard, dense and has very low porosity, being in-fact relatively impervious. Granite has excellent dimensional stability too.

As one of the best performing natural stones from a paving perspective, granite is only really surpassed by porcelain. That quality comes at a price though, and granite will tend to be more expensive than other natural stone.

There are typically two colour of granite paving that are widely used in landscaping and paving, although others are available:

- Silver Granite

- Black Granite

Granite paving slabs and granite setts (stone block paving) are both common and widely used.

- Granolithic Screed / Granolithic Paving / Granolithic Concrete

-

The use of aggregates being added to the surface of concrete to provide a harder-wearing, more durable surface. Typically, granite is used as the aggregate with granolithic screeds as it offers excellent performance and provides a desire aesthetic too.

See also Terrazzo.

- Grit Sand

- See Sharp Sand

- Haunch / Haunching

- Back filling with cement to secure a structure. The most common form of haunching in landscaping is done when securing the edge restraints for block paving.

- Kerb / Kerbstone

- Masonry units on the edge of a road, paved area, pavement or path, used to raise the edge and define the boundary of the paving. These can be stone or concrete. Usually they are laid on concrete bedding course and also back-filled (haunched) with concrete to secure them in place.

- Kiln Dried Sand / Jointing Sand / Silica Sand / Silver Sand / Beach Sand / Fine Sand

-

Jointing sand is a fine sand (ISO 14688-1:2002) and falls in the grade of 0.063–0.2 mm in particulate / grain size. It is washed and dried before being packaged in weatherproof bags. It is used mostly by landscapers to fill the joints when laying block paving, where its fine size and dryness mean it can be easily brushed into the newly laid blocks joints.

- Jointing Block Paving

- Laying Course / Laying Bed / Bedding Layer / Paving Bed

-

The course under the pavers (wearing course / surface course) that allows them to be laid on whatever is beneath (sub-base or existing concrete base). The laying course provides a bed that supports the pavers.

- Paving Slabs: laying course of 5:1 mortar (40-50 mm depth)

- Setts: laying course of 5:1 mortar (40-50 mm depth)

- Cobbles (river stones): laying course of 5:1 mortar (40-50 mm depth)

- Block Paving (concrete, stone & clay): laying course of compacted sharp sand (50 mm)

- Lime Mortar

-

A traditional mortar that use lime rather than of Portland Cement. Lime mortar is slower setting, more porous, more breathable, more flexible, less compressively strong and offers weaker bonding than Portland Cement based mortar. This is why its use in construction has significantly declined.

However, the properties that make this mortar less likely to be selected for everyday use, are actually why it is still ideal for certain projects. Lime mortar is especially useful in the repair, restoration and conservation of period and historic buildings. It breathability, weaker relative strength to old bricks and masonry (as a sacrificial component) and flexibility are key characteristics necessary when restoring older properties or using older/traditional construction techniques.

- Limestone

-

Limestone is a sedimentary rock, mostly composed of calcite, a form of calcium carbonate mineral CaCO3. Most limestone is derived as biological sedimentary rock (meaning it is formed from the accumulation of organic debris such as shell, coral, algal, and faecal deposits on the sea bed). Limestone is also formed chemically from water that is saturated with dissolved calcium carbonate materials that settle as a cement (often bonding with the biologically derived particles).

Limestone is a relatively soft stone (Mohs hardness of 2 to 4), but has excellent compression strength (up to 180 MPa compared to concrete at approximately 40 MPa). This means it is ideal as a material for paving, as it is soft enough to cut and work, but very strong when used as paving under compressive load.

Limestone is generally light coloured, in a white to light grey range. However, darker types such as Black Kadapha and Kota Blue are found when the organic content of the rock is higher.

Limestone paving has a distinct “orange peel” texture finish when riven, and feels soft and tactile. This finish makes limestone paving a popular choice and explains why it has been used in this role for millennia.

- Macadam

-

A road building process conceived by Scottish engineer John Loudon McAdam in the 1810’s – his works include Remarks on the Present System of Road-Making (1816) and Practical Essay on the Scientific Repair and Preservation of Roads (1819).

The road is constructed with a compacted sub-base of a coarse aggregate (20 – 75 mm) comprising low porosity angular stones. The angular stone lock together to form a stable mass. On top of this, a wearing course of a finer aggregate, also of angular stones that would form a solid interlocking mass when compressed, is added. This construction method was highly reliant on the grade of the aggregates and their angular shape to ensure stability and longevity.

- Metalled Road / Metalled Surface

- A road or path with a wearing course consisting of small stones (gravel) and fines, usually compressed to form a solid, stable mass suitable for wheeled traffic. The name derives from the broken stones and cinders often used to make and repair roads (from the Latin term metallum, which means “mine” and “quarry”).

- Mortar

-

A workable paste used to bond and point masonry. Mortar’s main function is to harden (cure) and bond/hold the stone, bricks, pavers or concrete blocks in place. The three most common functions for mortar in landscaping are:

- Bedding layer – mortar is used for the bedding layer/laying course on which slabs, cobbles or setts are laid. The mortar adheres the paving in place and provides strong bonding and stability between the paving and the sub-base.

- Structural bond – mortar is used to bond masonry together (stone, bricks or CMU/breeze block) and provides structural cohesion e.g. when bricklaying the mortar bonds the bricks together.

- Pointing – mortar is used to point more traditional paving such as stone cobbles and setts. Mortar is most commonly used to point walling such as garden retaining walls, knee walls etc. The role of pointing is four-fold:

- to fill the joints/voids between masonry units

- to prevent water ingression

- to be weaker than the surrounding masonry so it can be the sacrificial element that (as the cheaper material) is the easiest to remove/replace when repairs are needed

- to provide the aesthetic finish to the masonry.

Cement mortar using Ordinary Portland Cement (OPC) is the most common type of mortar used in landscaping and paving. For period restorations, building conservation and traditional builds, a lime mortar is often used or required.

- Masonry: Ashlar Block

- Ashlars or Ashlar blocks are large dressed stones used in masonry construction. Nowadays they tend to largely be used as decorative features, and are commonly used around door, hallways and other entrances.

- Masonry: Capping

-

Capping is often used synonymously with “coping”, as it is used to protect the top of walling from rainwater penetration and weathering. However, capping differs from coping in that its edges are flush to the face of the wall, with no overhang present.

There are generally five main types of wall capping:

- Cock ‘n’ hen capping – a vertical “dry-stone” style line of stones laid perpendicular to the line of the wall that form irregular peaks akin to the “comb” on a chicken’s head.

- Pitch face, half-round capping – dressed stones laid perpendicular to the line of the wall that have a hand-cut pitched or chamfered profile to achieve a rounded cross-section.

- Hogs Back / Half-Round / Rendered – – similar to pitch face capping, but either dressed stone (hogs back) or pre-cast half-round concrete laid in-line with the wall, custom render formed into a half-circle.

- Tiles / Slabs – One of the most common forms of capping is the simple use of tiles or paving slabs to line the top of a wall. Usually laid length-ways along the wall.

- Brick / Block – probably the second most common form of wall capping is the use of bricks or blocks. Usually laid in a soldier course perpendicular to the length of the wall.

- Masonry: Cill

- The carved stone or reconstituted stone beam at the bottom of a window. A window cill (sill if you’re American) will generally have a sloped angle down away from the building to allow water to run away from the property. It is largely decorative, but does help prevent water and moisture entering the property beneath the window. Most cills will have a drip grove on the lower edge to help droplets form away from the wall.

- Masonry: Stooled Window Cill

- A stooled window cill has flat platforms on either side upon which bricks or masonry blocks can be directly laid. If no platform/stool were present, the cill would likely have a larger joint with the brickwork to accommodate the slope of the cill. Therefore, stooled cills are designed to improve aesthetics and weatherproofing with a tighter, flusher fit between the bottom of the window and surrounding masonry.

- Masonry: Coping

-

Coping is used to protect the top of freestanding and parapet walls from rainwater and weathering. Coping can be made from a variety of materials such as stone, ceramic tiles, porcelain, concrete, metal (lead) or composite. Its role is to prevent water penetrating the wall, which could damage it. Coping protrudes from the wall (often featuring a drip-groove or cut on the underside of the overhang) and is designed to direct water away from the wall. The overhang is what differentiates coping from capping stones (which sit flush to the wall).

There are five general types of coping:

- Saddle / Twice-Weathered – this coping has two-sided pitched upper surface which allows water to drain either side of the wall. Generally used on freestanding walls, where the direction of draining is not important.

- Splay / Wedge / Once-Weathered – this coping has a single sloped upper surface where the gradient is designed to drain the water in one direction. These are used more often on parapet walls to ensure rainwater run-off is directed away from structures or terraces.

- Flat – this coping has no gradient, and does not encourage the water to run in a specific direction. Flat coping is generally used on low walls (knee walls, pony walls, half walls, dwarf walls) where it can be used for seating or as a surface for resting things upon.

- Decorative / Ornate – this type of coping features decorative elements and motifs. Generally these will tend to be saddle style coping with the decorative element running along the central ridge.

- Half-round / Hogs Back – this type of coping is similar in function to twice-weathered coping, in that the water will drain to either side. But, with this style of coping is rounded, with the cross-section of a half-circle.

- Masonry: Keystone

- The central block used in arches and vault that that locks the springers in place.

- Masonry: Springer

- Wedged shaped blocks used in arches and vaults used on either side of the keystone.

- Masonry: Pier Caps

-

Pier caps are masonry units designed to sit on top of brick/masonry piers, gate posts or pillars, to protect them from rainwater and weathering. The there are a variety of styles of pier caps, but the most commonly seen types are:

- Flat – a simple slab of concrete or stone

- Contemporary Apex – four sloped sides meeting at the middle like a gentle pyramid

- Neo-Classical Apex – four sloped sides meeting at the middle with neo-classical style cornice & entablature

- Stepped – like a step-pyramid, with each square level getting successively smaller

- Ornate – often with a neo-classical entablature and pediment, upon which an ornate element such as an urn, obelisk, orb, or eagle sits in the centre.

- Masonry: Voussoir

- Wedge shaped masonry used in arches and vaults that include springers and keystones. Most commonly seen in the arches over windows.

- Masonry: Head

- A window head is the stone, cast stone or brickwork element above the span of the window. Generally these are decorative, non-structural features (the structural support being provided via a steel lintel). However, structural cast stone window heads containing pre-tensioned or post-tensioned steel do exist.

- Masonry: Jamb

-

Jambs are the vertical elements on outer sides of the window. They differ from mullions (inner vertical elements between the frames/sash) and stiles (vertical parts of the sash/frame).

In architectural masonry, jambs will often be used in conjunction with other matching window surround elements, with window cills and head having matching styles to create a unified look.

- Masonry: Door Surround

- Stone or cast-stone masonry door surrounds can vary in style from neo-classical surrounds with porticos, entablatures and columns to more contemporary designs, with simpler, cleaner lines.

- Masonry: Window Surround

- Head – horizontal element above the window

- Cill – horizonral element with sloping ledge below the window

- Jambs – vertical elements on the outer edges of the window

- Mullions – vertical elements within the window between the window sashes/frames.

In architectural masonry, the window surrond is made up from the elements around the window that are not part of the sash/frame. Some people may refer to the surround as the casing, but this is not technically correct, as the casing will tend to be constructed from the same materials as the frame/sash (e.g. wood, PVC, metal) and sit within the surround.

The window surround comprises of the following:

- Masonry: Mullion

Mullions are the inner vertical elements within the window, between the window sashes/frames. They tend to be thinner than window jambs (which will be on the outer edges of the window).

- Masonry: Quoins

- Quoins are the stone corner blocks used to decorate the corners of buildings. Modern quoins will often be L-shaped in design to allow them to be laid more easily, following the course of the facing bricks.

- Masonry: Corbel

- A bracket-like structure designed to support the superincumbent weight of elements above it. Commonly seen in classical and medieval architecture.

- Masonry: Cast Stone

-

Cast stone or reconstituted stone is a precast concrete used as a subststiute for traditional cut natural stone masonry. It is widely used for most types of architectural masonry, offering a low-cost alternative to natural stone, but with similar or identical aesthetics.

One of the major advantages of cast stone when used in archirectural masonry is the colour control achievable through pigements used in production. This allows architects and builder to carefully select exactly the colouring they need for their building’s stonework.

- Masonry: Gable Vent

-

A gable vent is a traditional method by which passive ventialtion of an attic or roof space can be achieved. Usually, a gable vent is placed on either end of the roof, allowing air-flow and pressure differential to draw-out hot air and humidity from inside the roof space.

When external air flow is not directional towards the vent, but running perpendicular to it, the vent is still able to successful draw air from the roof space as it exploits the Bernoulli Principle (where faster moving air has a lower pressure), so the external low pressure turns the vent into a venturi (acting like a vaccum cleaner) and sucks the warm, humid air out of the roof space.

- Masonry: Kneeler

-

A kneeler is a piece of masonry used to change the vertical angle of a course and provide a seat/footing for the masonry that is not horizontal.

Kneelers are most commonly seen on gable coping where they sit at the base of the gable’s triangular shape supporting the rising coping stones.

- Masonry: Gable Saddle Stone

- A gable saddle stone is the masonry unit that sits on the top or apex of the gable’s triangular shape.

- Masonry: Gable Coping

- Like standard coping, gable coping is designed to protect walling from rainwater and weathering. It is located on the gable parapet wall at the end of the building’s pitched roof.

- Masonry: String Course (Band Course)

- A decorative line of masonry blocks or bricks, usually in a contrast colour to the facing bricks or blocks.

- Masonry: Plinth Course

-

A plinth course is a projecting course found near the base of a building or wall, used to step-out the line of brickwork or blockwork. A plinth course will usually have a chamfered profile.

Historically, wall plinths were designed to protect the base from damp and rain-splash. As walls generally used lime mortar, the plinth base was both breathable and thicker/ more robust, thus, achieving the aim of providing better damp protection.

However, as contemporary construction generally builds cementitious walls (which do not breathe like lime mortar walls), plinth courses are largely decorative, providing a more traditional / period look and feel, but serving little functional purpose.

- Masonry: Name/Date Stone

-

A datestone is an engraved stone or moulded-reconstituted stone block, usually embedded in the wall of the structure, that is inscribed with the name and/or date of the building.

Datestones are not very reliable as historical records of the age of a building, as often they are reused when a building is rebuilt, so bely the real age of the property, often predating the existing structure.

- Masonry: Balustrade

-

A series of balusters supporting a rail or banister, usually found on parapet walls, staircases and bridges. Balustrades are decorative features, providing an ornate screen and barrier that supports the rail.

The Balusters themselves can be simple turned stone (rounded/cylindrical in nature) or intricately carved (squarer, more geometrical in nature).

The purpose of the balustrade is aesthetic; it is there to add beauty, intricacy, craftsmanship, order, and create a sense of wonder/import.

- Masonry: Sand

- See Building Sand

- MOT Type 1 (Type 1 SHW clause 803)

-

Type 1 SHW clause 803 (formerly MOT Type 1) is an aggregate used as hardcore. In paving projects, it is used to construct the sub-base. When it is compacted, the aggregate settles and the fines fill the voids between the larger grade particles, creating a very stable and secure sub-base.

This construction aggregate grade contains fines and is graded from 40 mm to dust.

- MOT Type 3 (Type 3 SHW clause 805)

-

Type 3 SHW clause 805 (formerly MOT Type 3) is an aggregate used as hardcore where permeability and drainage are required. For paving projects, this is generally when permeable paving is being installed, and surface water needs to be able to penetrate the ground to soak away through the sub-base aggregate.

Type 3 SHW clause 805 has reduced fines, which means it is suitable for permeable paving and underground water collection systems as the reduced fines will not clog or inhibit drainage.

- Muck

- Nickname for mortar mix (4:1 bricklaying or 5:1 paving).

- Pavement

-

This has two general meanings with regard to hard landscaping:

- A paved area or surface, such as a patio, terrace or pathway

- A paved or asphalt covered pedestrian walkway on the side of a road that is usually raised above the level of the road surface.

- Pavé

- A sett or cobblestone (stone block paving) is often also called a Belgium Block; hence the French word “pavé” meaning cobblestone is used as a synonym for Belgium Block or sett.

- Paver

- 1) Any masonry unit used for paving. In the United Kingdom these are specified under BS 7533-101:2021.

- 2) A landscaper who specialising in laying paving.

- Paving Sand

- See Sharp Sand

- Paviour

-

- A person who lays paving (paver or landscaper).

- A machine for laying paving (e.g. mechanised block paving machine)

- Material used for paving (often used meaning setts)

- Pebble Paving

- As the name suggests, this is where rounded river pebbles (gravel 4-64 mm) are set in a cement mortar to create a paved area. Often, landscapers will align the pebbles to create patterns and motifs such as fans and waves. This is a nice technique to used in low foot traffic areas of the garden where aesthetics and the intricacies of the laying design will pay off.

- Picture Framing (decorative borders/edging)

- A design motif used on patios and driveways where a contrasting colour edge course is used on the border of the paving.

- Picture Framing (permeable paving joints)

-

When moisture is able to permeate through pointing in the joints of paving to leave damp patches on the edges of the slabs.

The solution to this issue is to replace the patio’s pointing with a waterproof replacement (epoxy based jointing compound).

- Pier Caps

-

A coping stone designed to specifically sit on top of walling piers. Pier caps are most commonly used for gate posts when a masonry pier has been used.

As with all coping, the function of a pier cap is to protect the brick/masonry pier from the effects of weather, and prevent rain and damp getting into the pier and causing damage to its structural integrity.

- Pitch

- The angle of the surface of a constructed object (usually roof). When referring to the angle of a patio, the term fall is generally used. A fall of 80:1 to 60:1 is generally recommended, ensuring water drains from your patio as desired.

- Pit Sand

- See Sharp Sand

- Plastering Sand

- See Building Sand

- Pointing Mortar

- See bricklaying mortar (4:1 building sand to Ordinary Portland Cement).

- Portland Cement / General Purpose Cement

-

The commonest type of cement used in landscaping and construction is Portland cement, from which it is often then subdivided into general purpose cement and high strength cement:

- CEM I 42.5R or CEM 42.5N “General Purpose Cement”

- CEM I 52.5R or CEM I 52.5N “High Strength Cement”

General purpose cement is suitable for most concrete, renders and mortars. Where an early strength gain is needed, then select an 52.5R type as this strengthens more quickly.

- Quadruple Stretcher (Edge Course)

- A stretcher-bond pattern edge course that is four blocks deep/wide.

- River Sand

- See Building Sand

- Roman Concrete

- Opus caementicium is noted for its durability and longevity. The use of pozzolanic ash and lime mix lent the concrete produced by Ancient Rome amazing properties (such as being able to be poured underwater) but most notably, is that this style of concrete hardens and becomes stronger and more homogeneous as it ages! This amazing property has been investigated by modern scientists and the production method of replacing fly ash with volcanic ash in concrete mixes has been “rediscovered” by contemporary civil engineers and builders to create stronger, longer-lasting concrete that is more environmentally friendly (using up to 60% less cement) see CEM IV type concrete.

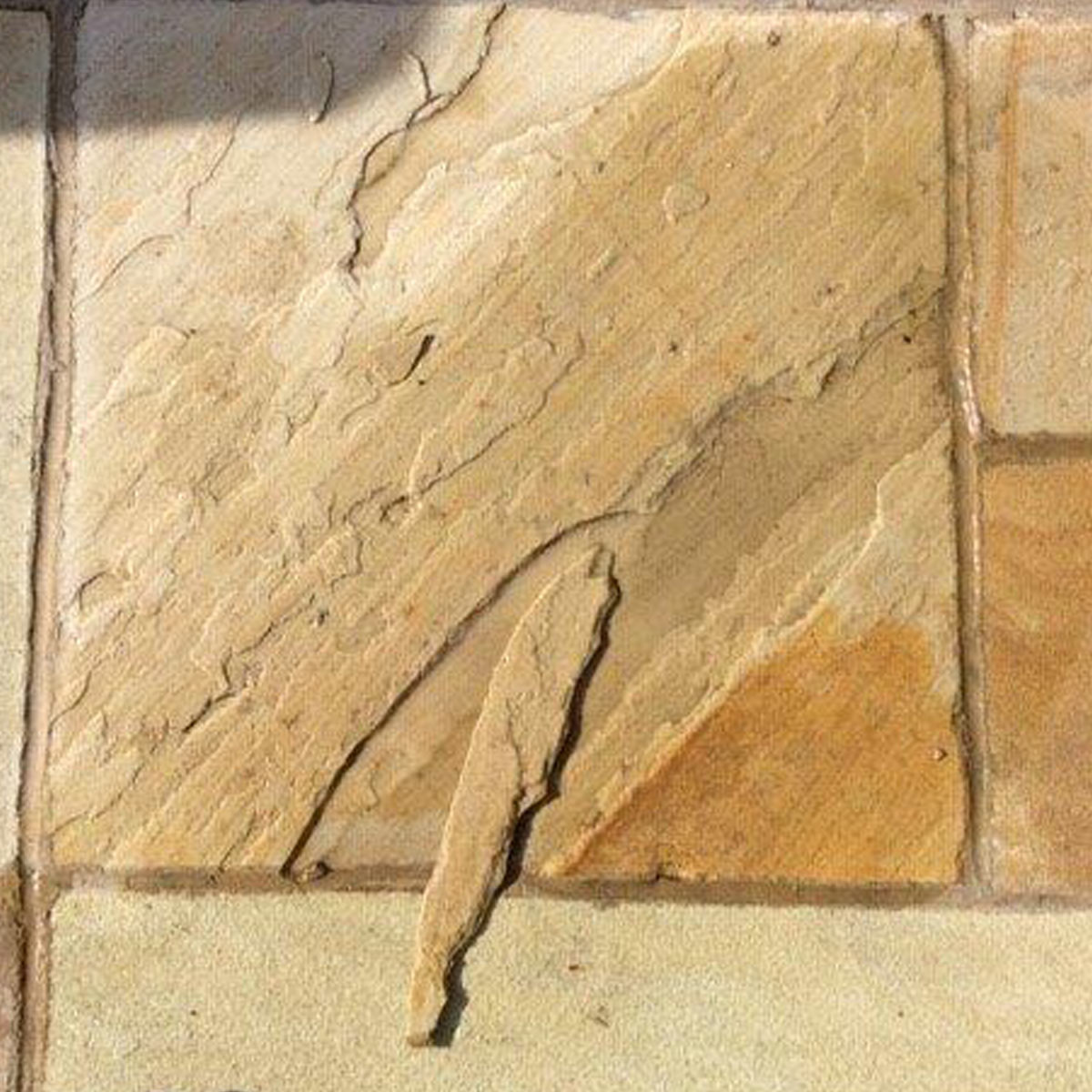

- Sandstone

-

Sandstone is a sedimentary rock, mostly composed of quartz sand, but also containing feldspar, silt and clay that have been formed into stone. It accounts for approximately 25% of all sedimentary rock. Sandstone is clastic (formed by the compression of particles together) rather than through organic or chemical processes. Because it is made from clasts (fragments of other rocks), the colour range of sandstone is wide. These colour “impurities” from sands and particulates which were laid down during its formation are what give sandstone its character and appeal.

Sandstone is a relatively hard stone (6-7 Mohs hardness) but its compressive strength (20 – 180 MPa) and flexural strength (5 – 30 Mpa) can vary widely depending on porosity and the amount and type of cement and/or matrix material present.

Sandstone is the most commonly used natural stone for patio paving. Most sandstone paving slabs in the United Kingdom are presently sourced from quarries in India.

Sandstone colouring ranges from light creamy yellows through to blacks and dark greys. The most common and popular sandstone paving colours tend to be fossil (light gold), buff (golden yellow to light tan), Kandla grey (light silver/dove grey to mid-grey), Raj/Autumn (light browns, chestnuts and sienna).

Sandstone slabs will generally either have a riven or honed surfaced finish. The edge finish will usually be one of three options; sawn (straight), hand-cut (near straight with small deviations) or tumbled (more rounded edges and corners with greater deviations on the profile).

Sandstone is also used to make setts and paving blocks, and these can also vary in finish, edge profile and calibration.

Other common landscaping products made with sandstone include edge stones and kerbs, coping stones and pier caps, garden features (spheres, benches, plinths and sculpture bases).

- Sealant / Sealing (Paving)

-

Sandstone, limestone and concrete paver are porous. Their structure has microscopic and tiny capillaries, cracks and fissures that can be penetrated by water and soluble debris and grime.

A paving sealer is designed to impregnate and fill these micro-fissures and capillaries. It adds a breathable protective layer that fills the capillaries and prevents ingress of water. This make the paving less permeable, protecting it from water and soluble deposits.

By reducing the porosity of the paving, the sealant helps prevent both physical erosion (freeze-thaw) and chemical erosion (acid rain). It also makes damp and moisture saturation of the paving more difficult, thus reducing issues such as efflorescence, iron-blooming and other mineral surface staining.

There are two common types of sealant:

- Natural finish – this type of paving sealer leaves the stone looking the same as before it was sealed

- Colour enhancing – this type of paving sealer creates a pseudo-wet look that darkens the tones and raises the vibrancy of the stone, so colours are enhanced.

- Setts

-

A sett is a small format stone block with a minimum dimension of 40 mm and maximum of 300 mm (BS EN 1342). A square (1:1) format is the most common format of sett (aka Belgium Block or Pavé), but technically setts include a wide range of stone block paving. The term setts is used by landscapers across the United Kingdom. Homeowners will tend to use the term cobbles or cobblestones when describing setts.

The two most popular types of setts used widely across the UK for driveway and garden paving projects are sandstone setts and granite setts.

- Shingle

-

Shingle is a type of gravel where typically one end of the stone is thicker than the other – creating an angular stone. This shape tends to mean shingle aggregates provide some interlocking stability, making them excellent for driveway gravel.

As well as being used for driveways, garden borders, and potting beds, shingle is often used for underground drainage as support material for pipes and soak-away chambers.

- Single Size Pack

- Paving packs are generally either contractor packs of mixed sizes, or single size packs, where all the paving is of the same size format.

- Single Stretcher (Edge Course)

- Stretcher bond sees block paving laid end-to-end (usually staggered with other rows). A single stretcher is an edge course that is one-block wide.

-

Sharp Sand is a coarse sand (ISO 14688-1:2002) and falls in the grade of 0.63–2.0 mm in particulate / grain size. It is used in paving to make the mortar bed cement mix when laying slabs and sett/cobbles, and it is also used to as the laying course itself (screed sharp sand) when laying block paving. Sharp sand is used particularly for making concrete, as it provides increased structural strength.

- Concrete

- Paving Bedding Mortar

- Block Paving Laying Course

- Slab

- Technically a slab is the name for a larger natural stone patio paver with a minimum width of 150 mm (natural stone slabs manufactured in accordance with BS EN 1341). However, this term is now used interchangeably to refer to all patio paving units larger than setts or blocks e.g. porcelain slabs and concrete slabs. Amongst landscapers in the south of the United Kingdom, slab is more commonly used to denote a patio paver.

- Slurry Primer / Priming Slurry

-

A slurry primer (aka bond bridge, primer, slurry coat) is painted onto the underside of paving immediately prior to laying. Its function is two-fold:

- Bonding – slurry primer improves bonding/adhesion between the paving and the laying course (bedding mortar)

- Barrier – priming slurry helps prevent leaching/osmosis of moisture, mineral salts and other cementitious materials from the laying course up into the paving above.

Priming slurry can also be used to help bond the following and ensure they remain firmly fixed in place:

- Coping stones

- Pier caps

- Steps

- Ornamental columns and pillars (sundials, statue bases etc)

- Soak Away

-

A soak away (soakaway) is an infiltration mechanism or method for returning surface drainage and storm water to the land. Generally, these are underground void structures connected via drainage to surface drains that allow storm water and rainfall to enter the void and then soak away into the ground in a controlled manner.

Soak away crates of 1m³ (1 cubic metre) are usually sufficient for every 50m² of paving. So if your paved area that drains into the soak away is 75m² in size, you will need your soak away to be 1.5m³ to handle that area of paving. However, you will also need to consider the size of roofs and their pitch when adjacent to the paved area when calculating surface water capture requirements for your soak away.

Your underground soak away will normally need to be located within the boundary of your property. It will need to be placed at least 5 metres from any buildings and 2 metres away from the boundary of the property.

The soak away crates will be buried wrapped in permeable geotextile material to prevent dirt and fines entering the chamber and clogging it. The crate will be placed in its trench, laid upon a layer of washed aggregate (e.g. shingle) with no fines. The crate will also be backfilled and covered with the same aggregate to ensure proper drainage. Top soil can then be returned over the soak away to hide its presence.

For house builders and developers, the soak away within each house plot may need to be included in your drawings as part of your SuDS (sustainable drainage systems) planning if that is one of your chosen capture and attenuation methods.

- Soft Sand

- See Building Sand

- Soldier Course

- A soldier course, in bricklaying and paving, is a single row of usually vertical/perpendicular bricks or blocks that appear like a line of drawn-up soldiers. In paving, this is often used for an edge courses that lays perpendicular to the interior blocks (end-on). In bricklaying, the most common uses of soldier course are 1) as coping on top of a wall and 2) as a decorative element above doors and windows (using a steel lintel for structural support).

- Springer (Voussoir)

- The base wedged-shaped masonry (voussoir) at the bottom of an arch or vault on which the arch/vault rests.

- Sub-Base

-

The sub-base is the course that lies under the laying course of a paving installation and above the natural soil/rock (sub-grade). The function of the sub-base is to provide stability and set the level and fall of the paving (drainage angle/gradient).

There are three types of sub-base constructed for domestic paving installations:

- Standard – compacted MOT Type 1 (Type 1 SHW clause 803) – usually 100 – 200 mm depending on the stability of the sub-grade/substrate under it.

- Permeable – compacted MOT Type 3 (Type 3 SHW clause 805) – usually 150 – 300 mm depending on the stability of the sub-grade/substrate under it.

- Bound concrete base – where there are local site specific issues with the sub-grade stability (such as boggy or sandy ground) a bound concrete base can be laid over an aggregate sub-base to create a concrete base (which acts as a de facto sub-base). When unbound blocks are being laid as the paving (such as a driveway), typically, the concrete base (impermeable) will require suitable drainage such as fin drains or French channel. This drainage will prevent the sharp sand laying course becoming saturated, allowing the water to drain past the concrete base.

Of these three methods, the standard MOT Type 1 compacted sub-base is by far the most common, with the other two methods only being used when necessary.

- Subgrade (formation level)

-

The deepest layer of a construction excavation, it is formed of natural/native material. Also known as the formation level, the subgrade is the level from which construction starts.

So, in paving, the subgrade is the lowest excavated layer of your patio or driveway installation. The subgrade should be compacted and graded/levelled as required in preparation for the installation of your sub-base, which will be laid on top.

- Substrate

- Although used synonymously with subgrade, the substrate is the term used to define the material level beneath any topsoil on which you will build. The common types of substrate are soil, rock, gravel, clay and sand.

- SuDs (Sustainable Drainage System)

-

Sustainable Drainage System or Sustainable Urban Drainage systems are methods used in house building and urban development to mitigate their effect on the natural water cycle, in particular surface run-off and water pollution.

SuDs seeks to mimicking natural drainage regimes, to reduce surface water flooding, improve water quality and enhance the amenity and biodiversity value of the environment.

- Storing or re-using surface water at source

- Decreasing flow rates to watercourses

- Improving water quality.

Parts of the UK suffered significant flash flooding in 2008. The Flood and Water Management Act 2010 was the government’s response and established SuDs as the new framework for drainage management.

- Swale

-

Low-lying ground, often a hollow or depression, which catches watcher and allows it to soak away. Often, damp and marshy.

Man-made swales are designed to slow and capture run-off water by spreading it over a wider area, reducing flow velocity and allowing the water to infiltrate the ground in a desired/designated area. Often, vegetation will be planted to assist in retarding water flow (grasses, reeds and willow being). Their functions are:

- Slow the movement of water through the landscape after heavy rainfall

- Reduce peak flows

- Form a temporary reservoir

- Direct water to a storage or discharge system

- Facilitate the absorption of water into the ground.

- Tarmac

-

Tarmacadam is a road surfacing material made by combining crushed stone, tar, and sand, patented by Welsh inventor Edgar Purnell Hooley in 1902.

It was based on the adding tar to a macadamed road surface to provide improved bonding, longevity, water resistance and grip for motorised transport.

It has largely been superseded by asphalt, which replaces the tar component with bitumen.

- Terrazzo

- Traditional Italian flooring based on ancient mosaics of Egypt, where either marble, quartz, granite or glass fragment are laid and bonded in cement that is then polished to a smooth surface, exposing the colourful polished fragments.

- Togher (Ireland)

- A term for a road or causeway from the Irish word tóchar (hut).

- Triple Stretcher Course (Edge Course)

- The use of three rows on the course that have been laid using a stretcher-bond pattern. Generally used for edge courses, but sometime used between different paving areas to create a visual border.

- Voussoir

- Wedge shaped masonry used in arches and vaults that include springers and keystones. Most commonly seen in the arches over windows.

- Voids / Voiding (Paving)

-

The holes that remain when a full bed of mortar has not been used. Usually the result of spot bedding. Voids should be avoided, and a full mortar bed should always be used. Voids can cause issues with your paving:

- Spots/stains where the mortar is drawing water from flooded voids up into slabs

- Damage to the sub-base and mortar from water in the voids, causing subsidence and instability

- Damage and loosening of the slabs, from freeze-thaw action from water collecting in the voids

- Higher risk of unsupported slabs cracking where the voids are not supporting the paving

- Insect infestations likelihood is higher as the voids provide the perfect home for ants and other insects.

- Wheeler

- A double track of large flat stones laid on traditional cobbled/setted streets to provide a smoother surface for carriage wheels.