In this article, we will explore what block paving is, why it is used for driveway paving, why it should be considered for patio and garden paving projects, and the variety of options available. This post is designed to be a useful reference for anyone interested in block paving and how it can be used to achieve different visual and functional effects. It is also a guide to the benefits of block paving and how it can add value to your property.

- What is block paving?

- Benefits of block paving

- Strength

- Durability

- Grip

- Versatility of style

- Cost of block paving installation

- Return on investment

- How does it compare to other options?

- Drainage and planning permission

- Block paving options

- Styles

- Materials

- Colours

- Finishes

- Bound and unbound paving

- Size options

- Summary

What is block paving?

Block paving is a term which covers a broad range of small-format paving. This includes concrete block pavers, natural stone setts and quarried blocks. A defining feature of block paving (in contrast with large format paving slabs) is its size:

Size

British and European standards govern both natural stone blocks (referred to as “setts”) and concrete block paving. These standards dictate the following dimensions:

- Stone setts – minimum dimension of 40 mm and maximum of 300 mm (BS EN 1342)

- Concrete block paving – minimum dimension of 50 mm depth and a maximum length of 4 times the depth measurement. (BS EN 1338)

Formats

Most paving blocks are square or rectangular.

Square formats are known as 1:1 with the most common sizes being 100 mm, 150 mm and 200 mm.

Rectangular blocks have a variety of formats and sizes within those ratios:

- 2:1 (twice as long as it is wide)

- 200 x 100 mm

- 300 x 150 mm

- 3:2 (three units for every two)

- 300 x 200 mm

- 150 x 100 mm

- 4:3 (four units for every three)

- 200 x 150 mm

- 4:1 (four units for every one)

- 200 x 50 mm

The shape of a sett or paving block will often determine the laying pattern of a driveway or patio. Some formats are more suited to particular styles than others, and there are paving patterns that can only be achieved by particular shapes/formats.

Often, block paving will have ranges or packs of mixed sizes that use a common width. This allows the different size blocks to be laid together using their common width as the width for each course/row of blocks, but allowing for variable length, for a more irregular, informal appearance, with something of a rustic/historic feel.

Read more on size options here:

Size options

Setts vs Cobbles: What is the difference?

River Cobble Paving

Historically, river cobbles were used to create paved surfaces. They were a cheap and readily available source of materials that could be collected from local rivers and streams, and did not require to be cut or dressed like setts.

Their round smooth surfaces (the result of physical erosion in flowing bodies of water) means there are no sharp or jagged edges to cut a foot (or hoof). They could cope with high traffic from carriages and horses. Consequently, river cobbles were widely used to pave streets, carriageways and driveways, footpaths and gardens.

The size of cobbles is technically defined as being between 64 mm and 256 mm in any dimension (with pebbles being smaller and boulders being large on the Wentworth scale).

“Cobbled” Paving

River cobbles were ubiquitous and used on most paved roads, carriageways and domestic driveways, so “cobble” became synonymous with a stone paving unit used on roads.

As the industrial revolution progressed, mechanisation was introduced into the quarrying and processing of stone. Canals and steam trains allowed heavy goods to be more widely distributed. These factors meant that stone paving units could be manufactured that had a flatter surface, sawn edges, that were cut to a uniform size. These stones were affordable, and able to be distributed through the new transportation networks of canals and railways.

So the river cobbled was replaced by these square and rectangular “setts” but the name cobble lived on. Hence, we still refer to olde wolrde setts of a traditional appearance as “cobbles”.

“Sett” is the technical term for natural stone block paving, so landscaping professionals are the primary users of this term, with most lay people still calling them cobbles.

Setts have been present in paving for millennia, especially for road construction (with Roman roads being the poster-boy example).

As discussed above, setts require processing and working to produce their square/rectangular shapes. Processing fettle edged (hand-cut) setts is labour-intensive, with masons carefully shaping the stone with a hammer. Manually sawing straight edges is even more labour-intensive.

With industrialisation and the improvement of processing and manufacturing techniques, combined with the ability to transport heavier loads, setts became a preferred method for paving more prestigious thoroughfares and affluent neighbourhoods from the later 18th century.

As the Industrial Revolution progressed, so the costs of quarrying, processing and transporting stone dropped. Consequently, setts were more widely used for paving and they became somewhat ubiquitous. However, they did retain something of their prestige, and that premium status survives to this day, with “cobbled” paving being highly desirable.

Benefits of block paving

Once the preserve of heritage sites or older properties, block paving has regained a place as a functional and visual design element. Both old and new properties use block paving for driveways, patios or garden paths and it has become a desirable feature of homes and businesses alike.

Strength

Due to a mechanical principle known as ‘size effect’, the strength of a material increases the smaller it becomes. There are two reasons for this: firstly, the larger an object is, statistically, the more flaws/weaknesses the material will contain that could cause failure; secondly, the larger an object, the more stored energy it possesses, so as force is exserted upon it, that stored energy must be released, so a failure is achieved more quickly, as there is more energy to trigger the failure.

An example that illustrates this easily would be comparing a glass window pane vs a glass marble in a series of strength tests – which one is most likely to break first? You know without having to think about it that the marble is going to win ever test, right? The same principle holds true for stone and concrete paving.

Types of Strength in Block Paving

Paving blocks can withstand significant weights and pressure that might crack larger paving units. When heavy vehicles or repeated foot traffic move across block paving, three types of strength are at play used to resist that force:

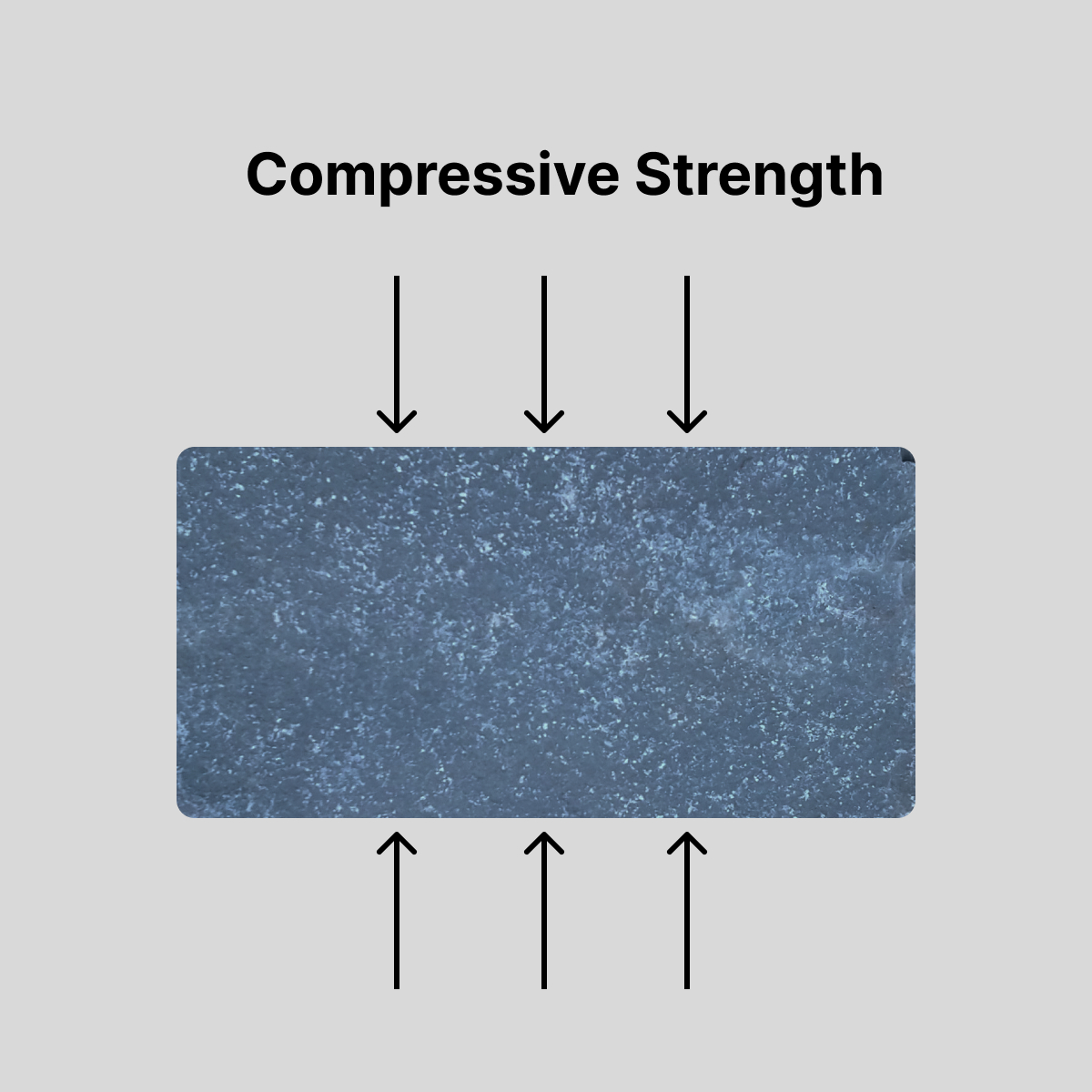

Compressive strength: This is how much capacity a block will have to withstand loads which try to push down/up (compress) and push/squeeze it together.

Comparative compression strength examples:

- brick greater than drinks can

- drinks can greater than grape

- grape greater than jelly baby

Where the length and width of a paving block is smaller relative to its depth, compressive force is quickly dispersed from the surface area to the edges, dissipating the compressive force efficiently.

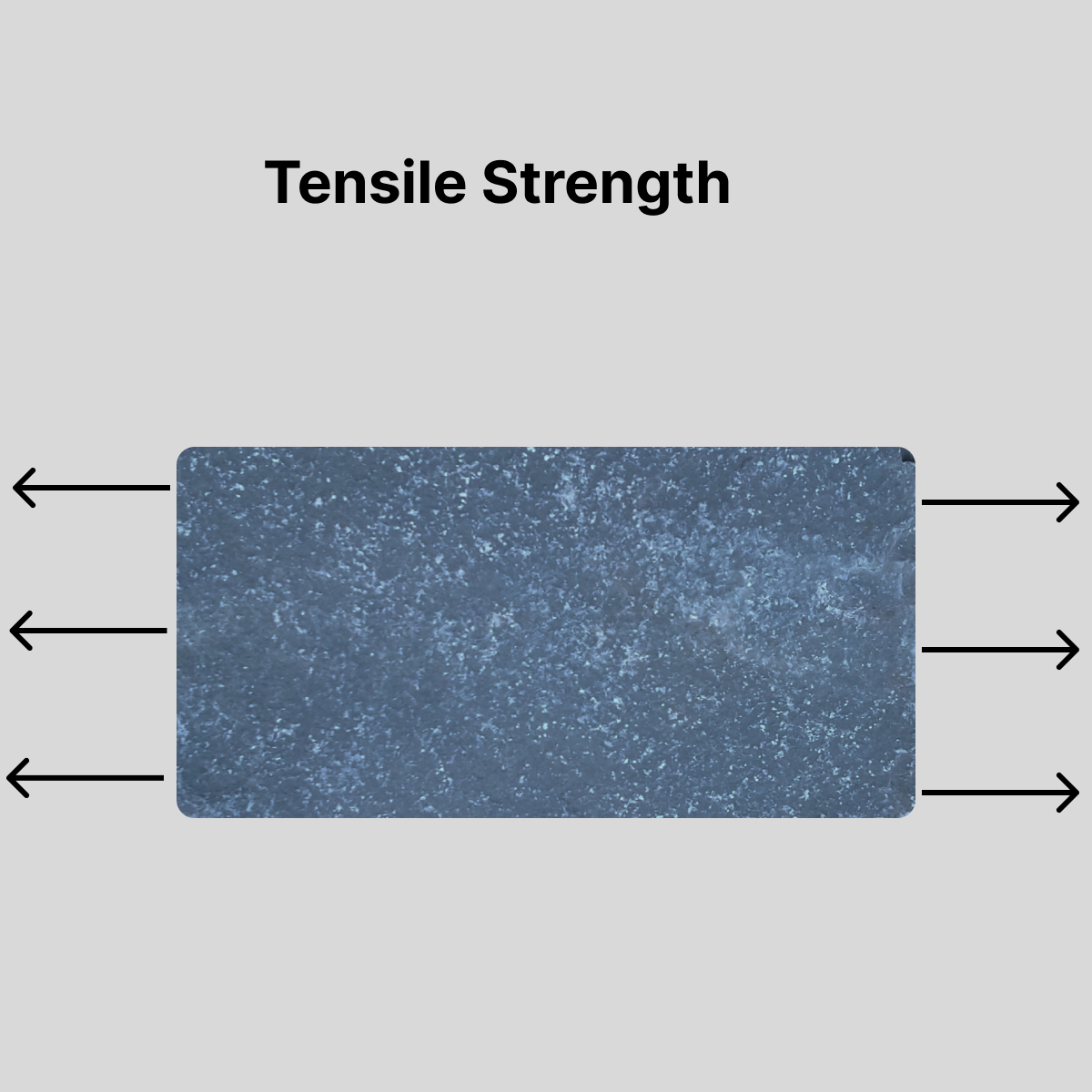

Tensile strength: A block with high tensile strength will withstand forces that might bend or stretch it.

Comparative tensile strength examples:

- rubber band greater than jelly baby

- jelly baby greater than slice of bread

- slice of bread greater than prawn cracker

For paving, bending is more common than stretching as a force that tests tensile strength. The materials (stone, concrete and porcelain) are brittle, so flexural strength (this is the material’s ability to bend, without breaking) is what determines whether is would crack when people or vehicles more across it. The thicker an object is, the stronger it will become to resist bending forces. The shorter an object is, the stronger it will become to bending forces. So block paving, by using a shorter and thicker format than slab paving, is able to resist bending forces more effectively, even if the same materials are used.

Paved areas are subject to stretching from ground movement and the forces that result from it. This means paving elements may develop flaws and cracks as they are stretched. In paving blocks, the tensile force that comes from ground movement is spread out over more than one block, as well as the jointing material between each block. So, smaller format blocks are exposed to fewer forces that test their tensile strength.

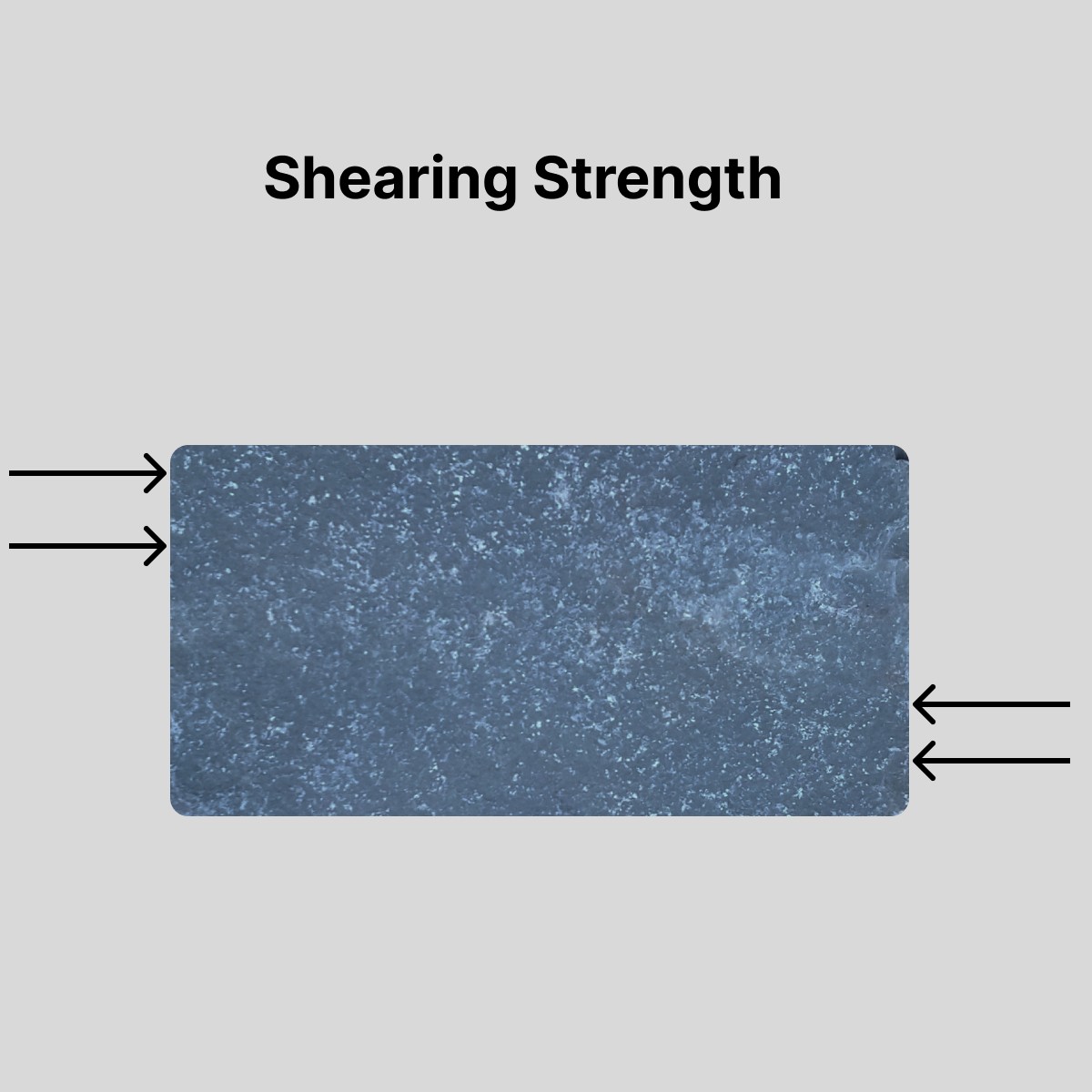

Shearing strength: When a material has high shear strength, it withstands a force that puts pressure on a parallel plane, like when guillotined (butter has a low shearing strength, steel has a higher shearing strength.

The larger the size of an object is, the more stored force there is to facilitate failure to allow shearing to occur. Likewise, the thinner an object is (relative to its overall size), the more energy there is relative to that thinner thickness. So, longer, wider, thinner paving slabs have lower shearing tolerances than thicker, narrower, shorter block paving units.

Durability

The properties of block paving ensure that it is very durable. It is less liable to cracks and fissures caused by impact or high compressive loads. Block paving inherently out-performs slabs when it comes to strength and durability due to the shape and size of the paving units. Using any paving material, when compared like-for-like, the size format of block paving enhances compressive, tensile and shearing strength. So, block paving always provides superior performance with regard to strength and durability.

Block paving has improved flexibility when it comes to land movement. The subgrade (the ground under the installed paving) can naturally shift and move, meaning the hard landscaping elements on top, faces forces trying to move them. With paving blocks, this will often mean the jointing between each block takes the brunt of any forces.

If this occurs with bound block paving, the mortar or jointing compound is the ‘sacrificial material’ that cracks/breaks, and it can simply be repointed.

With unbound block paving, the blocks might dance a little. This can go, one of two ways. Either the blocks spread out, and some wider joints may appear (that can easily be filled with more kiln dried sand), or they press together a bit more and the joining sand is compressed. In extreme cases, the blocks may be pushed entirely flush together (butt jointed). If this occurs, the blocks might need lifting, relaying and rejointing to prevent spalling and shaling.

Grip

Block paving in all its formats has decent anti-slip properties that are derived from some specific characteristics.

- Concrete blocks paving has a slight rough texture on the surface, and there are specific types that have additional granulated textured surfaces to enhance grip further.

- Natural stone blocks will often have a riven or textured surface, which helps with grip/traction.

- Natural stone blocks will usually have a profile that protrudes from the level of the jointing, creating relief that provides grip/traction.

- Porcelain setts will usually have an R11 rating, meaning they have excellent outdoor anti-slip properties.

Versatility of Style

Paving blocks are among the most versatile hard landscaping materials. With them, you can create a diverse range of styles and effects. It makes them useful in a range of different property types, from the rustic and ancient to the sleek and ultra-modern.

Block paving can be used as part of a main paving course, as a decorative edge or as part of more elaborate decorative features like the one pictured here.

Cost of block paving installation

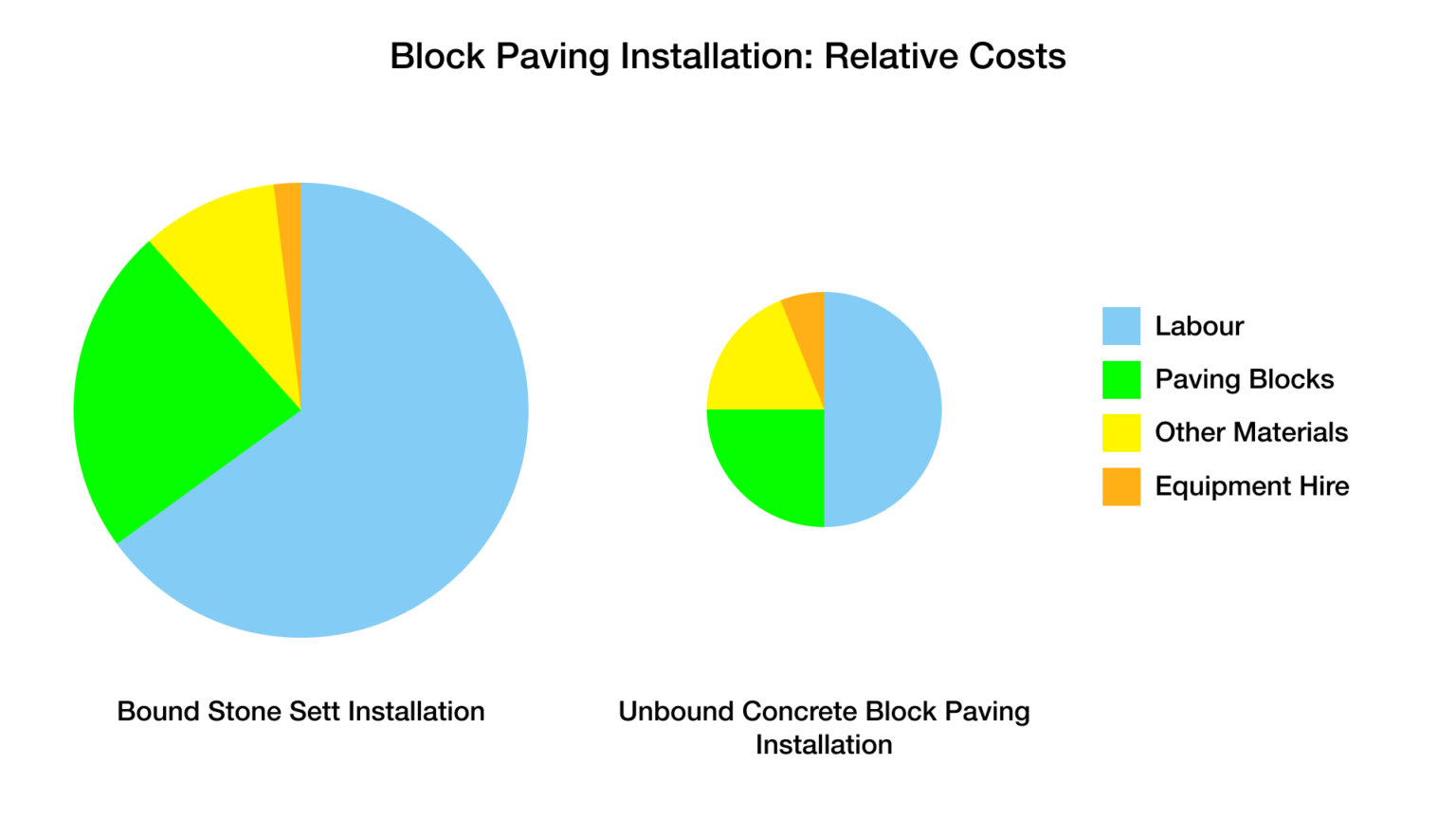

The cost of block paving installations can be broken down into the four broad categories: labour, paving blocks, other materials and plant/equipment hire. Depending on the type of installation, the percentage of total costs will vary slightly, but they will typically fall in the following ranges.

Below, is a diagram showing the relative costs of a bound fettled sett installation vs an unbound concrete block paving installation. As you can see, the bound (bonded with mortar) fettled stone setts will typically cost almost twice as much as a concrete block paving installation for the same coverage/area.

Return on investment

Block-paved driveways are viewable from the road, and when you come to sell your property, they will form a significant part of the buyer’s first impression. Private parking is a big draw for many new homeowners, both in terms of security and convenience. When that parking area has been constructed using block paving, its ‘kerbside appeal’ is dramatically increased.

Block paving adds an element of prestige and warmth, with a promise of a similar style inside the property. It has been shown in studies that a block paving driveway installation can add as much as 10% to the value of a property.

If you are considering block paving for your driveway, garden paths or a patio, then you will probably want to understand the relative costs of each installation type, so you can judge which type works best for your home, budget and property value. Here is a quick summary of the types and their costs relative to each other.

- Stone Setts (Bound) – Most Expensive

- Stone Setts (Unbound) – In the Middle

- Concrete Block Paving (Unbound) – Least Expensive

Let us breakdown some of those costs…

Cost: Bound Stone Setts

With this type of installation (the most popular method for fettled/hand-cut stone) the setts are laid on a course of mortar/concrete which ensures they are bonded – creating an inflexible paved surface. The setts are usually pointed with either mortar or an epoxy jointing compound.

As fettled/hand-cut setts often have a variable depth (uncalibrated), and higher dimensional tolerances than sawn stone blocks, they will usually require more work and manipulation to ensure decent fit and levels.

The expense of this type of bound sett installations is two-fold.

- Firstly, the setts will generally cost more per square metre than concrete paving blocks.

- Secondly, because the setts are bound in mortar and slightly irregular in shape and vary in depth, each stone must be adjusted/trimmed, individually placed and tamped to the correct level. This is time-consuming, and therefore, labour/time is the major underlying cost of this type of installation.

However, the aesthetic pay-off and value-add to a property is probably the largest from this type of installation. The wow-factor of a “cobbled” driveway or courtyard is significant, and well worth it with many period properties.

Costs: Stone Setts (Unbound)

There are essential two types of unbound sett installations that use a flexible construction. This first uses setts that are slightly irregular in size and depth, with fettled (hand-cut edges). These setts can be riven or brushed, and tumbled or untumbled (rounded-off edges). The second uses setts that have sawn edges, a calibrated depth and are dimensionally accurate blocks. For the sake of clarity, we will refer to this type as “stone blocks” and the rougher, more irregular ones as “fettled setts“.

Because stone blocks are sawn and calibrated (and have additional processing costs), they will cost more per square metre than fettled setts when comparing the same stone.

- fettled setts – less expensive

- stone blocks – more expensive

Looking at the installation costs, for fettled stone, these are much higher.

Fettled setts must be individually selected, sized/shaped, placed and levelled. Each sett has to be shaped and fitted (using a masonry hammer) to try and create as tight a fit as possible as they are laid. This is very labour-intensive and time-consuming. So this is where the bulk of the cost will come from. Also, fitting unbound fettled setts is a skill/craft that has become less common, and therefore, the more artisan landscapers who know how to do this properly can command a higher daily rate.

When assessing the cost of an unbound fettled sett installation, as well as the financial reward and return on investment derived from the improved aesthetics and kerbside appeal, consider the virtues of conservation and heritage. Period properties deserve preserving, using traditional building techniques and vernacular architecture methods. It is important to ensure paving is “in-keeping” with local materials and styles and preserve your property’s heritage. So where possible, we would always encourage adopting traditional and vernacular methods that have stood the test of time (and help encourage the Lindy Effect, so others follow suit).

Stone blocks are similar to concrete block paving, and consequently, these can be laid just like concrete block paving (in rows, resting on a bedding course of compacted sharp sand with fixed edge restraints holding everything in place, using kiln dried sand for jointing). This installation method is fast and readily known by block paving installer.

Cost: Unbound Concrete Block Paving

This is the cheapest and most common form of block paving. It is used for domestic (50 mm depth), light commercial (60 mm depth) and commercial projects (80 mm depth). The popularity of concrete block paving stems from four elements.

- lower cost of the man-made concrete blocks

- installation method is fast and efficient

- decent performance and lifespan (low lifetime costs)

- good choice of styles, colours and finishes meeting a variety of tastes and aesthetic requirements

With an unbound concrete block paving installation, the costs of groundwork (excavating to the substrate), setting the fall and drainage, and laying the sub-base, are comparable to any other installation. From that point, installing the edge restraints/kerbs and laying course (sharp sand/blind) are much more speedy and efficient. Once those are set up, the installation becomes very quick, with blocks being laid as fast as the installers can place them down, followed be cutting in blocks to the profile of the edge restraints, and then brushing-in the kiln dried jointing sand and a final compaction with the wacker-plate.

A typical 50m2 domestic driveway project would take 3-4 days for concrete block paving when compared to 6-9 days for a bound installation of setts. And that is why concrete block paving in generally favoured, as costs are 40-80% lower than natural stone sett projects.

In comparison to other renovations you can do to your house, block paving installation is fairly straightforward and can be done by non-professionals, which can cut costs significantly. It also sports one of the best returns on investment you can receive for household renovations and projects.

How does it compare to other options?

Block paving vs tarmac

Historically, tarmac took over as a material where block paving left off. It was a cheap alternative to block paving that was easy to install and offered a consistent, level “deck” for vehicles to move across. Functionally, it is more economic and dependable when time/budget was a factor. Consequently, many public spaces will utilise tarmac for driveways, parking areas and footpaths, despite its aesthetic shortcomings, as it is quick and cheap to install.

As a result, block paving is associated with heritage and history. Tourist attractions, stately homes and historic quarters often make use of cobblestone block paving to achieve a traditional feel to their paved spaces.

Tarmac will cheapen the properties’ aesthetics and make the property less desirable in appearance than block paving. However, a metalled/paved driveway will still add functional appeal as people always want convenient parking at home.

Block paving vs gravel

Gravel and chippings are common materials to be found on driveways and sometimes in the backyard or garden. They can be affordable and easy to install and offer good drainage, which is why many homeowners opt for them. However, gravel and chippings have a few disadvantages when compared to block paving.

Firstly, block paving can be laid on steeper inclines. When this is tried with gravel or chippings, it will tend to end up working its way down the slope and accumulating at the bottom, and sparse up-slope.

Secondly, in wet conditions, footwear will tend to become wet and stained as one walks across gravel or chippings, as the aggregate brushes against lower edges of your shoes or boots.

Thirdly, gravel/chippings are not fixed, flat and smooth, and have a slightly uneven surface that can also move. Therefore, gravel and chippings have less sure-footedness and stability for pedestrians. So for the elderly, frail, and young children/toddlers it poses more challenges and hazards.

Fourthly, even when geotext and other membranes are used during installation, gravel/chipping drives seem to be more prone to grass and weeds taking root, which means more weeding is required. As gravel drives age, this problem will worsen.

Block paving vs printed concrete

Printed concrete is designed to mimic the beautiful visual effect of block paving. It is not dissimilar to regular concrete installation, except that it involves a significant coloured concrete pour on which patterns are printed, and then sealed with a pigmented sealer.

Even the with the best installer of printed concrete, it never looks like authentic block paving. It will tend to have a uniform/homogenous look, and the sealant/pigment tends to make it look like painted concrete.

Furthermore, many installers will take short-cuts and not properly use rebar reinforcement, fibreglass strengthening, or an appropriate amount of expansion joints. This means that in practice, patterned concrete driveways often deteriorate much more quickly than they should, and even when best practice is followed, they will last about 50% of the age of a block paving driveway.

Drainage and planning permission

As with all renovations and upgrades to your property, it is important to be aware of potential planning permission requirements.

When it comes to driveways at the front of your home, there is a requirement under sustainable drainage systems (SuDS) planning to capture and soak-away all rain water and run-off within the bounds of your property. If you are unable to do this for some reason, and run-off water has to enter the public road/drain system, then your driveway will need planning permission prior to installation.

Your major consideration is flood water and how it runs off the paving. Since 2010, planning authorities have been increasingly more prescriptive on how flood water interacts with driveways through SuDS legislation. These legislative efforts have been designed to combat overflowing the public drainage systems and ensure water returns to the land on the property.

What does this mean in practice? It means:

- Any area over 5m2 at the front of your house that doesn’t use permeable paving AND doesn’t provide water run-off into a permeable area will need planning permission.

At the time of writing, this is the only instance where you will need planning permission for a block paved area.

Very simply, it means that you should either opt for permeable concrete blocks that will allow water to soak-away directly under the paved area, or use run-off drainage and soak away systems, so the water remains within the bounds of your property.

Common methods of ensuring rainwater is captured within the bounds of the property are:

Garden Capture – the fall/gradient of the paving directs surface water flow towards lawns, flower beds or gravel trap borders where it can naturally soak away. This is the most common and easiest way to capture water within the bounds of your property.

Underground Soak-Away – water is carried from a slot or gully drain via underground drainage pipes to a soak-away crate or perforated pipe (akin to a French drain).

Rainwater Harvesting – an underground reservoir (connected to drainage channels), that has a pump connected to above-ground water-stowage (such as a water butt) so the captured water can be reused to water the garden.

Permeable Paving – using paving that allows the rainwater to pass directly through it and soak into the ground under the driveway. This will require the use of permeable jointing aggregate (3-5mm) and MOT Type 3 (Type 3 SHW clause 805) as the sub-base material, which has reduced fines and will also allow water to drain through it.

It’s worth bearing in mind that a dropped kerb to accommodate a driveway will need permission too.

If you are planning to create a block paved area anywhere other than the front of your house, you will not need planning permission.

Block paving options

Styles

The style of block paving you can choose from roughly corresponds to four broad and interlinked categories of building design. These are:

- Traditional

- Modern

- Rural

- Suburban

These should be thought of as four vectors in a grid rather than mutually exclusive categories. However, it is worth exploring some general rules for each style. This will help you make a decision about what type of paving block you should use for your property.

Traditional Style

Traditional style is a broad term which can mean different things to different people, depending on their background and location. For our purposes here we are looking at both rural and suburban traditional properties. This can include Victorian town houses as well as rustic cottages.

Rural traditional houses can be very old. In some cases, they will have protected features, including stonework and landscaping. This means there can be a requirement for certain materials that are aesthetically similar. Block paving for such properties will likely be natural or natural looking and gently weathered.

Suburban traditional properties are from (or based on designs from) suburban houses that pre-date the space age. Up until the late 1950s, new housing developers would draw on decorative architectural movements. This means there was an emphasis on ornamentation and making a property as beautiful as possible. Movements included ‘garden suburbs’ (with an emphasis on greenery) and period style housing (Queen Anne and Georgian Style), and the very common 1930s Semi-detatched.

Block paving for these properties should reflect the era they were made, and use can be made of interesting design motifs

Modern Style

When a property is constructed according to modernist architectural style, it is often very stripped back and free from decorative elements. Modernist architects seek minimalism paired with functionality. There is a desire for simplicity of form and definition over ornamentation.

Suburban modern properties are either constructed as part of a wider movement or built to contrast with older properties in an area. Simple cubist designs and brevity of style are the hallmarks of suburban modern, and block paving for this kind of property should follow suit. Concrete is widely used as a material, especially amongst 1970s buildings, though it is possible to use natural stone if it has been sawn and honed.

Rural modern properties also make use of simplistic aesthetics and no-frills design. They may use glass and timber in their construction in order to visually complement the natural environment. Block paving for a modern rural building will continue to favour the sleek and simple, but may also use honed and smooth natural stone as well as concrete.

Materials

The choice of material for block paving plays a large part in the function and aesthetic of a paving project. Some materials have characteristics that are more desirable in given situations than others. Whether you are looking at natural stone or concrete block paving each type has qualities that make it ideal for certain applications.

Sandstone

Sandstone is a beautiful sedimentary rock which is desirable for its wide range of colours and unique cross-bedded patterns. This makes it a great choice for garden block paving that requires bold colours and classic visual appeal.

Available Formats

Depnding on the edge profile, sandstone block paving can be laid bound or unbound. They are available as follows:

Sawn Edge (Unbound) These sandstone sawn stone blocks can have tumbled (weathered/aged) or standard straight edges and can have either honed (flat) or riven (light ridged) surfaces. They are typically available in the following common formats:

- Mixed Size Packs

- 200 x 150 mm

- 150 x 150 mm

- 100 x 150 mm

- Single Size Packs

- 200 x 100 mm

- 100 x 100 mm

Fettled/Hand-cut (Bound/Unbound) These sandstone setts can have tumbled (weathered/aged) or fettled edges and generally will have riven (light ridged) surfaces. They are typically available in the following common formats:

- Mixed Sized Setts

- 200 x 150 mm

- 150 x 150 mm

- 100 x 150 mm

- Tudor Cobbles

- 400 x 400 mm

- 300 x 200 mm

- 200 x 200 mm

- 200 x 150 mm

- Single Size Packs

- 200 x 100 mm

- 100 x 100 mm

Limestone

This type of natural stone has been used for construction since antiquity, so it’s little surprise that we associate it with prestige and tradition. Limestone block paving is an excellent choice for period driveways and paving projects that need a period aesthetic.

Available Formats

Limestone paving blocks can be laid with or without a bond. Formats available include:

Bound Fettled/hand-cuts edge profiles that can also be tumbled (such as Denby Limestone). These Limestone setts will typical have a riven surface (light ridges):

- Mixed Sized Setts

- 200 x 150 mm

- 150 x 150 mm

- 100 x 150 mm

- Tudor Cobbles

- 400 x 400 mm

- 300 x 200 mm

- 200 x 200 mm

- 200 x 150 mm

- Single Size Packs

- 200 x 100 mm

- 100 x 100 mm

Unbound – It is possible to lay limestone paving blocks unbound, and this is more likely when the blocks have sawn edges. Edge profiles can be either normal or tumbled (aged/weathered).

- Mixed Sized Blocks

- 200 x 150 mm

- 150 x 150 mm

- 100 x 150 mm

Granite

Granite is a highly durable igneous rock with a naturally coarse-grained surface. Of all natural stone, it is the most hard-wearing and highest in compressive strength, which makes it perfect for driveway paving.

Available Formats

Granite setts are generally bound paving blocks. Bound granite setts are available as:

- 200 x 100 mm

- 100 x 100 mm

Because granite is an extremely hard rock, producing granite setts with a straight or sawn edge is very difficult and therefore very expensive. For this reason it is very rare to find installations of unbound sawn granite blocks.

Slate

Like granite, Slate is a highly water-resistant and hard-wearing material. Though it has a limited colour palette, the dark tones are rich and deep and sometimes highlighted with purples and rusty browns. They are an excellent choice for decorative borders and motifs.

Available formats

Slate almost always has a straight sawn edge. That means slate paving blocks can be bound if they have a shallow depth. Any that have a depth of 50-80mm can be laid unbound.

- Single Size Setts

- 200x 100 mm

- 100 x 100 mm

Concrete

Concrete paving blocks can be manufactured in a wide assortment of colours and finishes. As a result, they are highly versatile and can add to the visual appeal of both traditional and modern properties.

Available formats

A major benefit of concrete paving blocks is the variety available. Concrete can be manufactured and cut to a number of sizes. This means there are a number of styles to choose from:

Mixed Sized Blocks – these paving systems can be either antique/traditional (rumbled/rounded edge) or modern/contemporary (straight or small bevel edge) and will have a common width dimension, so the can be laid in courses/row of the same size, with varying lengths

- 200 x 150 mm

- 150 x 150 mm

- 100 x 150 mm

Single Size Blocks – these can also have rumbled, straight or bevelled edge profiles. These single size blocks are often used as decorative inlays or edge courses.

- 200 x 100 mm

- 100 x 100 mm

Dutch Pavers

These were traditionally made out of clay but the term now applies also to concrete blocks that have a 4:1 format.

- 200 x 50 mm

Concrete paving blocks generally come in three thicknesses, with each depth signifying different functional use cases.

- 50 mm depth (domestic use)

- 60 mm depth (light commercial use)

- 80 mm depth (commercial use)

Porcelain

Porcelain is one of the most durable materials that can be used for paving. Porcelain setts have a superior strength to natural stone or concrete and can be manufactured to mimic the visual appearance of a wide variety of rock and stone types, masonry or even timber. They are vitrified, which means that they are waterproof, making them easier to clean and have twice the lifespan of other kinds of paving block.

Like slate, porcelain blocks generally have a straight/sawn edge profile which makes them ideal for unbound block paving. The inherent strength of porcelain means that it can withstand high loads without having to be exceptionally thick. However, there are examples of porcelain blocks that have up to 60 mm in depth.

It should be noted that porcelain paving blocks remain uncommon, though some manufacturers are beginning to explore this possibility (as porcelain is by far away the best performing material available for paving applications).

Colours

There is decent range of colour options to choose from when selecting block paving. Block paving will typically be made up of blends with colour variation, so that the overall hue/appearance is generated from a patch-work like mix of individually distinct blocks. So materials, such as porcelain, granite and slate will have more uniform colour variation.

Sandstone paving blocks have a wide spectrum of colours that range from black and grey through red and brown to golden and light pink.

Limestone blocks commonly come in black/dark grey, grey, light grey, blue, beige or buff.

Granite has a unique speckled colour pattern of whites, greys and blacks. Typically these will be sold as silver, grey and black/carbon granite. Red and green granite setts are rare.

Basalt setts tends to be black/charcoal/dark grey or grey with small white speckles.

When we look at concrete blocks, there is almost an entire rainbow of colour to be found, as dyes can be added to the concrete mix when it is being processed. However, the most popular colours that are redily available tend to be silver/light grey, charcoal/dark grey, brindle/brick red, autumn/terracotta, buff/sand, and ochre/brown.

Buff, Fossil & Golden

Buff-coloured stone encompasses a range of tones centred on light sandy, almond, blonde, muted gold and wheat. This colour works well in areas that require something bright and warm.

Beige & Sand

Beige is the colour of untreated natural wool. It has been described as greyish yellow, but with paving blocks the colour palette stretches from buff and khaki through to lighter colours like cream, wheat and sand.

Brown, Umber, Chestnut and Russet

The brown colour group bridges the spectrum between beige and red. Paving blocks in this range are between dark chocolate and coffee to walnut and umber, along with tan, ochre and sienna.

Orange (Terracotta, Ochre, Sienna & Autumnal)

The orange colour group includes sandstone colours such as Modak, terracotta clay pavers and common concrete block paving colours such as autumn blend). Colours range from dark blood orange through to copper, burnt sienna, auburn and bronze, with terracotta being the most common colour.

Red & Brindle

The colours in the red group range from burnt sienna and oxblood to muted orange and rust, with “brick red” being how most people commonly percieve these colours. Red-toned paving blocks can work well for those seeking a more warmer palette and aesthetic.

Grey & Silver

Grey block paving covers a range between charcoal/anthracite at the dark end of the spectrum and silver ordove grey at the light end. Grey setts and cobbles are an ideal match for those looking for a traditional cottage garden block paved patio. Grey and silver concrete block paving are typically best sellers, as their colour means they blend in with many properties and work with a many aesthetics.

Black & Charcoal

Black setts are a great choice for anyone who needs a high contrast border, or an impressive dark block paved driveway or patio. Black riven and tumbled setts will create a traditional look, and honed, straight sawn setts will offer a more modern feel. Both are excellent decorative elements. Charcoal block paving is popular as both the main infill colour and also regularly used as either an inlay course or edge course decoration.

Blue

In the context of paving blocks, blue is often a highlight found in grey blocks. Paving which has shades of blueish grey offer an air of heritage, old-world charm and history.

Finishes

The surface texture of paving blocks also has a variety to choose from. Surfaces can be riven, light riven, textured or honed, each of which has visual appeal unique to them as well as slip resistance. It’s important to remember that natural stone, like sandstone, has a porous surface which can lead to moisture damage. But with sealers and regular maintenance, all stone will continue to look vibrant and beautiful, whatever its surface finish.

Texture and Light Texture Surface

Textured surfaces are common to concrete paving blocks. The texture is a continuous series of marks applied to concrete before it hardens to improve grip and surface friction.

Riven Surface

Riven finishes are common to natural stone paving blocks. When a stone is quarried, it is split down the grain to reveal the ridges and marks of the stone’s surface. On a riven surface, these ridges and furrows are pronounced and can help create grip.

Light Riven Surface

Light riven finishes have a more subtle sequence of ridges and furrows than riven surfaces. This creates a more subtle effect and a more consistent texture to the touch. Typically light riven surfaces are associated with limestone and slate.

Smooth/Honed

Smooth and honed finished paving blocks have an even, flat finish. These can be especially effective for borders and decorative edging. Honed or flat block are more manufactured/processed, and therefore, their aesthetic is tied into more modernist and contemporary styling.

Edge profiles

The edge profile can have a significant effect on the appearance and application of a paving block. It can dictate how and where the block is positioned and jointed, and each profile appeals to different design styles.

Straight/Sawn

The technological advent of mechanical power saws and machine tooling saw the adoption of sawn straight edges in the finishing and dressing of stone. Consequently, setts and blocks with sawn straight edges have a modern and contemporary feel, as this is when stylistically they became more widely adopted. The sawn straight edge allows these stone blocks to be laid unbound (akin to concrete block paving) on a screed sharp-sand laying course, with kiln dried sand jointing.

Hand-Cut (Fettled)

Hand-cut edge profiles are when a block has been cut to size using a masonry chisel or mason’s hammer. The edge profile is slightly irregular and often will appear to have the appearance of an inverted bevel, where the mason has fine tuned the edge to achieve the desired dimension required of the sett/block.

Tumbled

Tumbled edges are where a paving block with fettled/hand-cut edges is ‘tumbled’ in a large mechanical metal drum to create a more rounded profile. This is done to give these stone blocks are more time-worn, weathered and aged appearance, making them more appropriate for period and historic properties and buildings. Tumbled stone block paving tends to be less uniform in appearance, with more irregular edges, corners and rounded profiles, but consequently, they work very well in traditional settings where period or rustic aesthetics are needed.

Bound and unbound paving

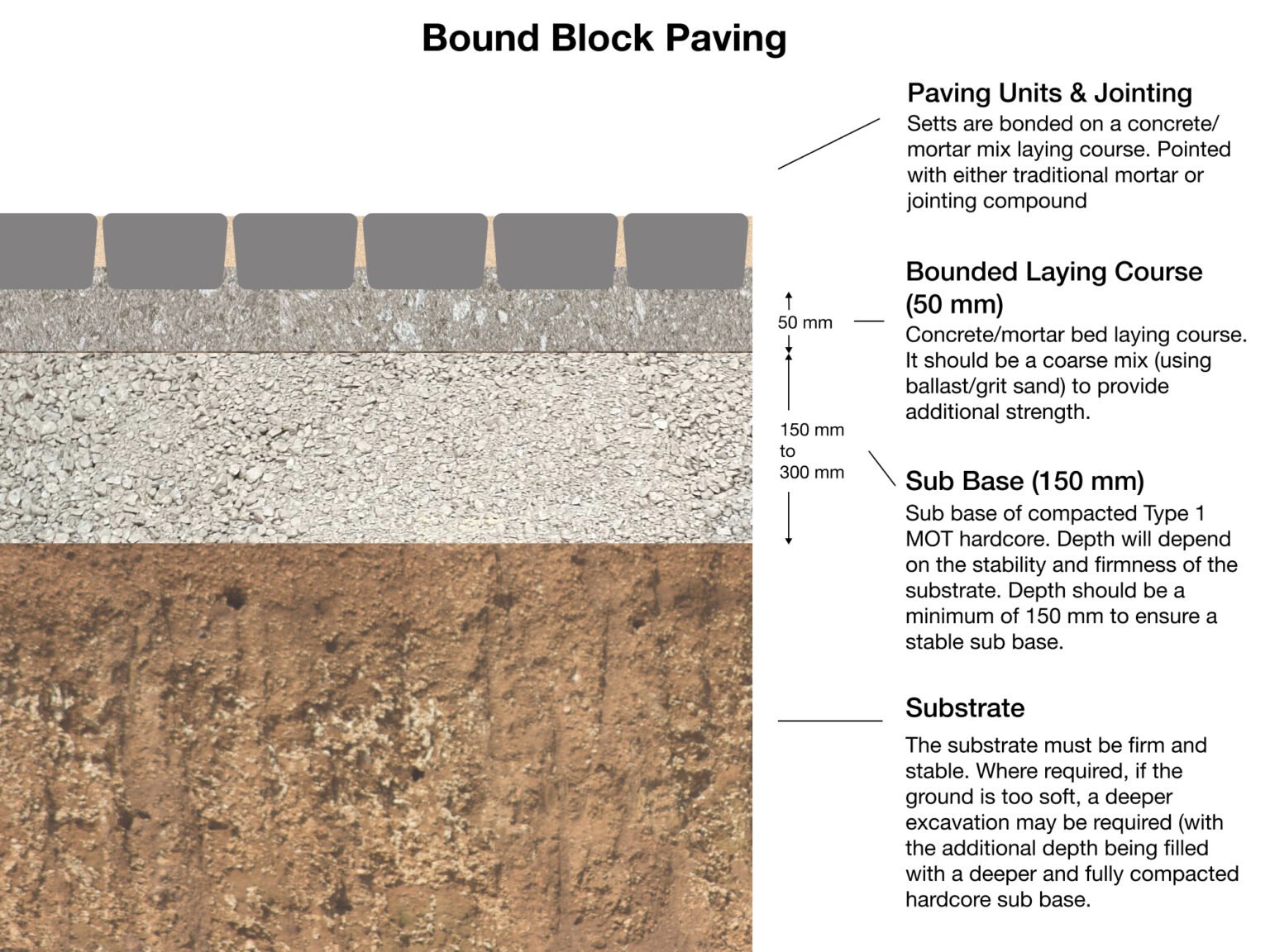

Bound block paving uses a cementious material laying course (usually either a dry or wet mortar mix). This material forms the bond between the sub-base and the setts/blocks and locks everything in place, creating a rigid construction. A bound block paving installation has low movement and has both high durability and high stability due to its more cohesive nature.

Bound installations are generally used when the setts are less dimensionally uniform and their shapes are more irregular. The laying course (mortar bed) allows you to manage the more awkward shapes, allowing you to set levels and orientation individually for each sett as required.

Riven/fettled setts can have some pretty broad tollerances and dimesional variation. So a bound installation allows the installer to lay these tradtional stone without having to hand dress and fit each stone, by using the mortar bed laying course to hold and set things in place. This avoids the painstaking sizing, trimming and fitting of each stone.

Bound Block Paving – In this type of installation the blocks or setts are bonded to the laying course (which is a full mortar bed).

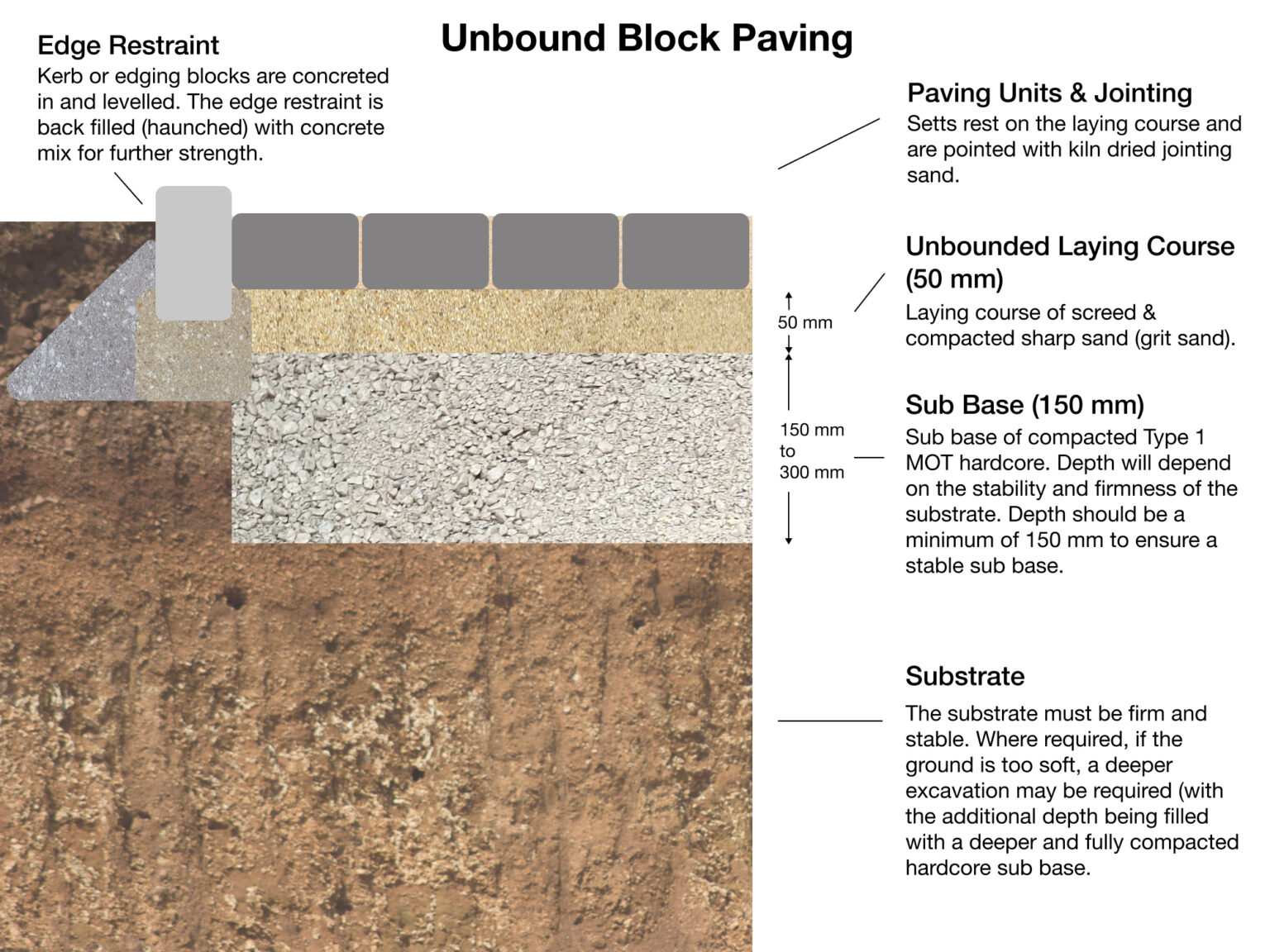

Unbound block paving is laid on a bed of compacted screed sharp sand or aggregate. It is jointed with either kiln dried sand or a fine aggregate (depending on the permeability required). It relies on edge restraints to ring-fence the paved area and hold the blocks in place within the perimeter.

Unbound block paving is fast to lay and install. Because the blocks are laid unbound, they can also be lifted and replaced easily if necessary too.

There are some disavantage to unbound block paving installation. Firstly, they are less suited to steep inclines, where gravity and downward pressure and lead to over-compressing on blocks at the bottom of the slope (sometimes forcing them to pop up), whilst leaving them loose and opening up near the top of the slope. Secondly, as underlying ground shifts and moves over time, the unrigid nature of these blocks means they will move and shift too, likewise creating areas where they are compressed or too loose.

Unbound block paving – in this type of installation the blocks rest on a laying course of compacted screed sharp sand. The blocks are held (constrained) in place via edge restraints (kerbor edging stones).

Size options

The size and shape of block paving is an important consideration when planning a driveway or patio. Natural hewn stone can have fettled edges (hand-cut and slightly irregularly) which are more suited for traditional properties, whereas blocks which have been sawn with straight edges, and are dimensionally calibrated to a particular size, are ideal for contemporary style paving projects.

Dimensions

According to BS EN 1342:2012, a sett must have a minimum working thickness of 40mm. The depth of block paving gives it the means to endure higher traffic and heavier loads. For that reason, it is common for setts and cobbles to measure between 40-100mm in depth.

Length and width also play a significant part in what kind of pattern you choose. Regular sized paving blocks fall under square setts or rectangular setts, and they can be utilised either as a single sized format or as mixed sizes and shapes.

Square Setts/Blocks

Square blocks can be laid in matrix/grid patterns, such as stack bonds or staggered in stretcher/bricker bonds. They can also be used to create interesting decorative edging or motifs like fans and circles. Where angles inform these patterns, wedge-shaped blocks may also be required, and professional landscapers will cut a block into the shape needed using a mason’s hammer.

Rectangular blocks

Rectangular blocks can create elegant and elaborate patterns for the main body of the paving. Popular patterns include basket weave, herringbone (as seen in this picture) and stretcher bond. They also make great edge courses or borders, such as soldier courses or pencil line inlays.

Single Size

When a landscaper buys a single-size pack of paving blocks, they are looking for a regular shape. These will work well for those who want symetry and consistency in their project, and once chosen, the paving laying pattern is relatively simple to execute.

Mixed sizes and contractor packs

Landscapers often use a variety of sizes and shapes to create interesting and complex paving features. It can take forward planning, a little creativity and technical skill to create a mixed-size patio, but when done well, the effect can be very attractive.

We have a whole article dedicated to paving pattern styles on the link below:

Summary

Block paving has the potential for a great amount of creativity. Understanding the characteristics we’ve looked at above can help to unlock that potential and use paving blocks to create elegant and exciting paving projects. The materials, size/shape, finish and colour all play a part in how the paving will look and how it will function, so each need to be considered carefully. If you are thinking of creating a block paving project, refer back to this guide as you make your purchasing decisions.